Overview

Ever wondered what makes alloy steels so special? Today, we dive deep into the world of Special Steel 20MnCr5/1.7147 Alloy Steel, a popular choice in various industries due to its unique properties and versatile applications. This article will explore everything you need to know about this alloy, from its composition and characteristics to its numerous applications, advantages, and even some limitations. Let’s embark on this metallurgical journey!

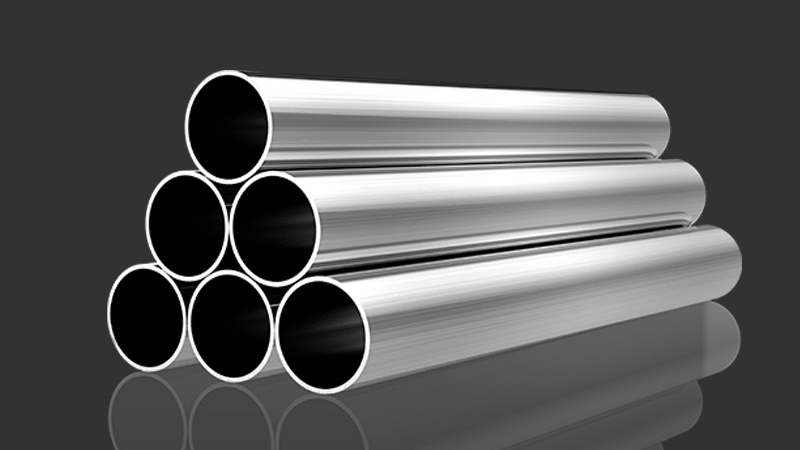

What is Special Steel 20MnCr51.7147 Alloy Steel?

Special Steel 20MnCr5, also known by its numerical designation 1.7147, is a case-hardening steel widely used for its excellent mechanical properties and wear resistance. This alloy is primarily composed of manganese (Mn) and chromium (Cr), which significantly enhance its strength and durability.

Composition and Properties

| Element | Percentage |

|---|---|

| Carbon (C) | 0.17-0.22% |

| Silicon (Si) | 0.40% max |

| Manganese (Mn) | 1.10-1.40% |

| Phosphorus (P) | 0.025% max |

| Sulfur (S) | 0.035% max |

| Chromium (Cr) | 0.80-1.10% |

Key Properties

- Hardness: 60-62 HRC (after case hardening)

- Density: 7.85 g/cm³

- Tensile Strength: 600-800 MPa

- Yield Strength: 450 MPa

- Elongation: 10-14%

Applications of Special Steel 20MnCr51.7147 Alloy Steel

This steel’s balanced properties make it ideal for a variety of applications. Let’s explore where and why it’s used.

Common Applications

| Application Area | Description |

|---|---|

| Automotive Industry | Used for gears, crankshafts, and camshafts due to its strength. |

| Mechanical Engineering | Ideal for components like shafts and machine parts. |

| Tool Manufacturing | Used in making cutting tools and dies. |

| Aerospace Industry | Employed in high-strength, wear-resistant parts. |

| Heavy Machinery | Suitable for durable and robust machine components. |

Specifications, Sizes, Grades, and Standards

When choosing 20MnCr5 steel, it’s crucial to understand its specifications, available sizes, grades, and the standards it meets.

Specifications and Sizes

| Specification | Detail |

|---|---|

| Grade | 20MnCr5, 1.7147 |

| Available Sizes | Diameter: 6-300 mm, Length: up to 6m |

| Standards | DIN 17210, EN 10084 |

Grades and Standards

| Grade | Standard |

|---|---|

| 20MnCr5 | DIN 17210 |

| 1.7147 | EN 10084 |

Suppliers and Pricing Details

Finding the right supplier is essential for obtaining high-quality steel at competitive prices. Here’s a list of notable suppliers and their pricing details.

Suppliers and Pricing

| Supplier | Location | Price (per kg) | Contact |

|---|---|---|---|

| ThyssenKrupp | Germany | $1.50 | [email protected] |

| ArcelorMittal | Global | $1.45 | [email protected] |

| Nippon Steel | Japan | $1.55 | [email protected] |

| Voestalpine | Austria | $1.60 | [email protected] |

| Tata Steel | India | $1.40 | [email protected] |

Advantages and Limitations of Special Steel 20MnCr51.7147 Alloy Steel

Like any material, 20MnCr5 alloy steel has its strengths and weaknesses. Let’s compare them.

Advantages

| Advantage | Description |

|---|---|

| High Wear Resistance | Excellent for applications requiring durable, hard surfaces. |

| Good Toughness | Can withstand significant stress and impact. |

| Excellent Hardenability | Can be heat treated to achieve high hardness levels. |

| Versatility | Suitable for a wide range of applications across industries. |

| Machinability | Easy to machine in its soft state, making manufacturing simpler. |

Limitations

| Limitation | Description |

|---|---|

| Cost | Higher than some other common steels due to alloying elements. |

| Heat Treatment Required | Needs heat treatment to achieve desired properties, adding cost. |

| Corrosion Resistance | Not as resistant to corrosion as some stainless steels. |

| Availability | May not be as readily available in all regions. |

Comparing Special Steel 20MnCr5/1.7147 with Other Alloy Steels

How does 20MnCr5 stack up against other popular alloy steels? Let’s see.

Comparison with Other Alloy Steels

| Property | 20MnCr5/1.7147 | 42CrMo4 | 16MnCr5 |

|---|---|---|---|

| Hardness | 60-62 HRC | 28-32 HRC | 58-62 HRC |

| Tensile Strength | 600-800 MPa | 900-1200 MPa | 750-1000 MPa |

| Yield Strength | 450 MPa | 750 MPa | 500 MPa |

| Elongation | 10-14% | 12-15% | 10-13% |

| Main Alloying Elements | Mn, Cr | Cr, Mo | Mn, Cr |

| Applications | Gears, shafts | High-strength parts | Gears, shafts |

Specific Metal Powder Models

For those working with powdered metals, here are some specific models of metal powders suitable for 20MnCr5 applications.

Metal Powder Models

| Model | Description |

|---|---|

| PM-20MnCr5-01 | Fine grain powder for precision parts manufacturing. |

| PM-20MnCr5-02 | Coarse grain powder for larger, robust components. |

| PM-20MnCr5-03 | Ultra-fine powder for additive manufacturing and 3D printing. |

| PM-20MnCr5-04 | High-purity powder for aerospace applications. |

| PM-20MnCr5-05 | Spherical powder for uniform density and strength. |

| PM-20MnCr5-06 | Atomized powder for improved flowability in powder metallurgy. |

| PM-20MnCr5-07 | Alloyed powder with enhanced properties for specialized uses. |

| PM-20MnCr5-08 | Custom blend powder for specific industrial requirements. |

| PM-20MnCr5-09 | Low-cost powder for general-purpose applications. |

| PM-20MnCr5-10 | Heat-treated powder for immediate use in high-stress parts. |

FAQ

| Question | Answer |

|---|---|

| What is 20MnCr5 alloy steel used for? | It’s used for gears, shafts, camshafts, and other high-strength, wear-resistant components. |

| How is 20MnCr5 different from 42CrMo4? | 42CrMo4 has higher tensile and yield strength but lower hardness compared to 20MnCr5. |

| Can 20MnCr5 be welded? | Yes, but it requires preheating and post-weld heat treatment to avoid cracking. |

| What are the main alloying elements in 20MnCr5? | The primary elements are manganese (Mn) and chromium (Cr). |

| Is 20MnCr5 corrosion-resistant? | It has limited corrosion resistance compared to stainless steels, requiring protective coatings. |

| What industries use 20MnCr5 alloy steel? | Automotive, aerospace, mechanical engineering, and tool manufacturing. |

| What is the hardness of 20MnCr5 after heat treatment? | It can reach 60-62 HRC after case hardening. |

| How does 20MnCr5 compare to 16MnCr5? | 20MnCr5 has slightly better mechanical properties and higher wear resistance. |

| What are the machining properties of 20MnCr5? | It is easily machinable in its annealed state. |

| Where can I buy 20MnCr5 steel? | Suppliers like ThyssenKrupp, ArcelorMittal, and Tata Steel provide 20MnCr5 alloy steel. |

Conclusion

Special Steel 20MnCr5/1.7147 alloy steel stands out due to its excellent combination of strength, hardness, and toughness. Its diverse applications across various industries, from automotive to aerospace, underline its versatility and reliability. Understanding its properties, advantages, and limitations helps in making informed decisions for your projects. Whether you’re sourcing the raw material or specific metal powders, this comprehensive guide equips you with the knowledge to leverage this alloy’s full potential. So, next time you encounter a high-stress engineering challenge, remember that 20MnCr5 just might be the steel you need.