Overview of 42CrMo Steel

42CrMo steel, a low-alloy high-strength steel, is renowned for its robustness and resilience. It is widely used in the manufacturing sector, especially for making heavy-duty mechanical parts such as gears, shafts, and components exposed to high stress and wear. This steel is highly prized for its excellent hardenability, toughness, and good mechanical properties. But what makes 42CrMo steel so special? Let’s dive into its intricate details, properties, applications, and more.

Chemical Composition and Properties of 42CrMo Steel

42CrMo steel stands out due to its unique chemical composition which gives it exceptional mechanical properties.

Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.38 – 0.45 |

| Silicon (Si) | 0.17 – 0.37 |

| Manganese (Mn) | 0.50 – 0.80 |

| Chromium (Cr) | 0.90 – 1.20 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 930 – 1080 MPa |

| Yield Strength | ≥ 780 MPa |

| Elongation | ≥ 12% |

| Reduction of Area | ≥ 45% |

| Impact Toughness | ≥ 63 J |

| Hardness (HB) | ≤ 217 (annealed state) |

The combination of Chromium and Molybdenum provides 42CrMo steel with exceptional hardenability, while the low phosphorus and sulfur content enhances its purity and toughness.

Applications of 42CrMo Steel

42CrMo steel is versatile and finds application in numerous industries due to its strength and durability. Here’s a breakdown of its common uses:

| Industry | Application |

|---|---|

| Automotive | Gears, shafts, axle components, steering knuckles |

| Aerospace | Aircraft landing gear components, engine parts |

| Machinery | Heavy-duty gears, machine tool spindles, high-stress fasteners |

| Oil and Gas | Drill collars, drill rods, valve bodies |

| Construction | Structural components, high-strength bolts |

This steel’s ability to withstand high stress and wear makes it a go-to material for parts that endure heavy loads and harsh operating conditions.

Specifications, Sizes, Grades, and Standards

Specifications and Standards

42CrMo steel conforms to various international standards ensuring its quality and suitability for different applications.

| Standard | Description |

|---|---|

| ASTM A829 | Standard Specification for Alloy Steel Plates |

| DIN 1.7225 | German Standard for Alloy Structural Steel |

| GB/T 3077 | Chinese National Standard for Alloy Structural Steel |

Sizes and Grades

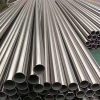

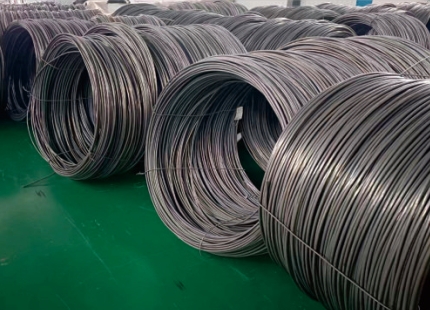

42CrMo steel is available in various forms including plates, bars, and tubes. Here are some common sizes and grades:

| Form | Size Range |

|---|---|

| Plates | Thickness: 10mm – 500mm |

| Bars | Diameter: 10mm – 600mm |

| Tubes | Diameter: 10mm – 500mm, Length: up to 12m |

Grades of 42CrMo steel often include designations like 42CrMo4, reflecting slight variations in the composition that meet specific application needs.

Suppliers and Pricing Details

When sourcing 42CrMo steel, choosing a reputable supplier ensures you get quality material that meets your specific requirements. Here’s a look at some top suppliers and typical pricing:

| Supplier | Product | Price (per kg) | Location |

|---|---|---|---|

| ArcelorMittal | Bars, Plates | $1.50 – $2.00 | Global |

| Baosteel Group | Bars, Plates | $1.40 – $1.90 | China |

| Thyssenkrupp | Bars, Plates | $1.60 – $2.10 | Germany |

| Voestalpine | Bars, Plates | $1.70 – $2.20 | Austria |

| Nippon Steel | Bars, Plates | $1.55 – $2.05 | Japan |

Prices can vary based on market conditions, order volume, and specific requirements like heat treatment or surface finish.

Advantages and Disadvantages of 42CrMo Steel

Advantages

| Advantage | Description |

|---|---|

| High Strength | Provides excellent load-bearing capacity. |

| Good Hardenability | Allows for uniform hardness throughout the material. |

| Toughness | Capable of withstanding significant stress and impact. |

| Versatile | Suitable for a wide range of industrial applications. |

| Wear Resistance | High resistance to wear and tear, extending the lifespan of components. |

Disadvantages

| Disadvantage | Description |

|---|---|

| Cost | Higher cost compared to plain carbon steels. |

| Machinability | More challenging to machine compared to lower alloy steels. |

| Welding | Requires careful preheating and post-weld heat treatment. |

Metal Powder Models for 42CrMo Steel

In the realm of additive manufacturing and powder metallurgy, 42CrMo steel is also available in powder form. Here are ten specific metal powder models:

- 42CrMo4-1.5M: Standard powder for general applications.

- 42CrMo4-2.0M: Enhanced molybdenum content for improved toughness.

- 42CrMo4-HC: High carbon variant for better wear resistance.

- 42CrMo4-LP: Low phosphorus variant for higher purity.

- 42CrMo4-Si: Silicon-enhanced for improved hardenability.

- 42CrMo4-TF: Thermally fused powder for superior bonding.

- 42CrMo4-FG: Fine grain powder for detailed part production.

- 42CrMo4-AM: Additive manufacturing optimized for 3D printing.

- 42CrMo4-SP: Spray powder for coating applications.

- 42CrMo4-MS: Multi-size particle distribution for diverse applications.

Each powder model is designed to meet specific needs in manufacturing processes, ensuring the best performance for the intended application.

Comparison: 42CrMo Steel Versus Other Alloys

When choosing materials, it’s essential to compare 42CrMo steel with other similar alloys to understand its unique benefits and limitations.

42CrMo Steel vs. 4140 Steel

| Property | 42CrMo Steel | 4140 Steel |

|---|---|---|

| Strength | Higher tensile and yield strength | Good strength, slightly lower |

| Hardenability | Excellent, deeper hardening | Good, but not as deep |

| Toughness | Superior | Good, but slightly less |

| Cost | Higher | More affordable |

| Applications | Heavy-duty parts, aerospace | General machinery, automotive |

42CrMo Steel vs. 40Cr Steel

| Property | 42CrMo Steel | 40Cr Steel |

|---|---|---|

| Strength | Higher tensile and yield strength | Lower than 42CrMo |

| Hardenability | Superior, especially for larger sections | Adequate for smaller sections |

| Toughness | Better impact resistance | Sufficient for moderate stress |

| Cost | Higher | Lower |

| Applications | High-stress parts, oil and gas | General mechanical parts |

FAQ

What is 42CrMo steel commonly used for?

It’s used for making heavy-duty parts like gears, shafts, and components that face high stress and wear.

How does 42CrMo steel compare to other steels?

42CrMo steel offers higher tensile and yield strength, better hardenability, and toughness.

What are the limitations of 42CrMo steel?

It is more expensive and challenging to machine, and requires careful welding practices.

What is 42CrMo Steel?

42CrMo is a medium carbon alloy steel grade commonly used in China according to the GB/T 3077 standard [1]. It’s known for its good balance of properties including:

- Mechanical Strength: Offers good overall strength

- Hardenability: Can be effectively hardened through heat treatment

- Wide Applications: Used in various machinery components

What are some equivalent steels to 42CrMo?

Here are some international equivalents to 42CrMo steel:

- ISO Standard: 42CrMo4

- European Standard (EN10083): 42CrMo4 (This may be referred to as the closest equivalent)

- Japanese Standard: SCM440

How is 42CrMo different from 42CrMo4?

42CrMo4 is a broader classification that encompasses the Chinese 42CrMo steel. 42CrMo4 typically refers to the steel following the European standard EN10083, and may have slightly different properties due to minor variations in allowed chemical composition.

What are the applications of 42CrMo steel?

Due to its good strength and hardenability, 42CrMo is commonly used in various machinery components, including:

- Gears

- Connecting rods

- High-strength bolts

- Other important parts requiring good mechanical properties.