Giới thiệu

Imagine a material that seamlessly blends exceptional strength, resilience, and the ability to be shaped into complex forms. That’s the magic of 18CrMo4/1.7243 alloy steel, a workhorse in the engineering world. In this exploration, we’ll delve into its composition, properties, applications, and everything in between. So, buckle up and get ready to discover the hidden potential within this remarkable steel!

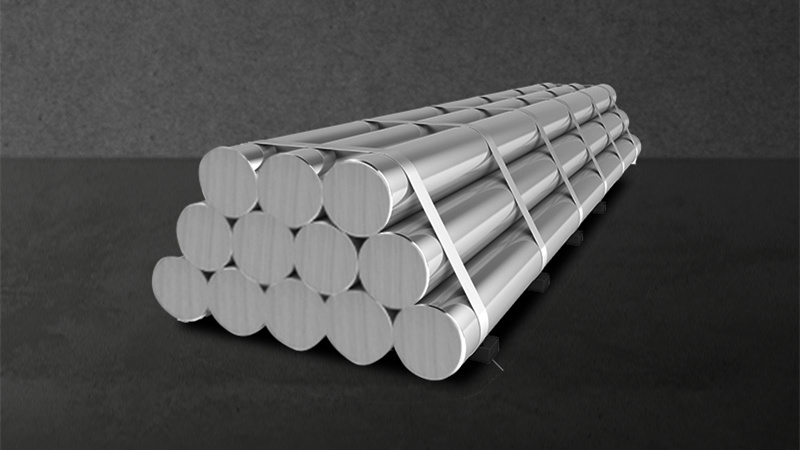

Tổng quan về Thép hợp kim 18CrMo4/1.7243

18CrMo4/1.7243, also known as EN 1.7243, is a versatile alloy steel renowned for its high strength, excellent hardenability, and good weldability. It’s a low-carbon, case-hardening steel, meaning it can be carburized to create a hard, wear-resistant outer layer while maintaining a tough inner core. This unique combination makes it ideal for a wide range of demanding applications.

Thành phần Hóa học

The exceptional properties of 18CrMo4/1.7243 stem from its carefully balanced chemical composition. Here’s a breakdown of the key elements and their roles:

- Carbon (C): The primary strengthening agent, present in a range of 0.15% to 0.21%.

- Silicon (Si): Improves hardenability and aids in deoxidation, with a maximum content of 0.4%.

- Manganese (Mn): Contributes to strength and enhances hot working characteristics, typically ranging from 0.6% to 0.9%.

- Phosphorus (P) and Sulfur (S): Unwanted elements kept to a minimum (max 0.025% P and 0.035% S) to prevent brittleness and hot shortness.

- Chromium (Cr): The hero of high-temperature strength and corrosion resistance, with a content between 0.9% and 1.2%.

- Molybdenum (Mo): Further enhances hardenability and high-temperature strength, present in a range of 0.15% to 0.25%.

Key Properties of Thép hợp kim 18CrMo4/1.7243

18CrMo4/1.7243 boasts a compelling set of properties that make it a standout choice for various engineering applications:

- High Strength: After quenching and tempering, this steel can achieve a remarkable tensile strength of up to 1100 MPa (159,500 psi), enabling it to handle significant loads without breaking. Imagine it as the tireless workhorse in the steel kingdom!

- Excellent Hardenability: This steel readily absorbs carbon during the carburizing process, resulting in a hard and wear-resistant outer layer that can withstand friction and abrasion. Think of it like a superhero’s tough skin, ready to take on the challenges of demanding environments.

- Good Weldability: While preheating is recommended due to its chromium content, 18CrMo4/1.7243 can be effectively welded, making it a versatile option for complex structures.

- Good Machinability: This steel offers reasonable machinability in its annealed condition, allowing for efficient shaping and fabrication.

Applications of 18CrMo4/1.7243 Alloy Steel

The exceptional properties of 18CrMo4/1.7243 translate into a wide range of applications across various industries:

- Automotive: Gears, shafts, crankshafts, connecting rods, and other critical components that require high strength and wear resistance.

- Construction Machinery: Parts subjected to high stress and wear, such as gears, sprockets, and excavator components.

- Oil and Gas Industry: Rods, shafts, and pressure vessels that need to withstand demanding environments and high pressure.

- Agriculture: Gears, shafts, and other components in agricultural machinery that experience significant loads and require durability.

- General Engineering: A broad spectrum of applications benefit from 18CrMo4/1.7243, including shafts, gears, pins, bushings, couplings, and fasteners in various machinery and equipment. Its ability to handle heavy loads and resist wear makes it a reliable choice for industrial applications.

Advantages and Limitations of 18CrMo4/1.7243 Alloy Steel

Advantages:

- Exceptional Strength: Compared to low-carbon steels, 18CrMo4/1.7243 offers significantly higher tensile strength, allowing for the creation of lighter yet stronger components. Imagine replacing a bulky steel component with a sleeker 18CrMo4/1.7243 counterpart – a win for both performance and weight reduction.

- Superior Wear Resistance: The carburized case of 18CrMo4/1.7243 provides excellent resistance to wear and tear, extending the lifespan of components in applications like gears and bearings. It’s like a built-in shield against friction, ensuring components function smoothly for longer.

- Good Weldability: While preheating is necessary, 18CrMo4/1.7243 offers good weldability compared to some high-alloy steels. This allows for the creation of complex structures and facilitates repairs when needed. Think of it as a steel that plays well with others, integrating seamlessly into welded assemblies.

- Good Machinability: In its annealed condition, 18CrMo4/1.7243 can be machined at reasonable speeds, making it a cost-effective option for complex shapes. This allows for efficient manufacturing and reduces production time.

Limitations:

- Lower Corrosion Resistance: Compared to stainless steels, 18CrMo4/1.7243 offers moderate corrosion resistance. It’s best suited for applications where corrosion isn’t a primary concern or can be mitigated through surface treatments.

- Not for High-Temperature Applications: While offering some high-temperature strength due to chromium and molybdenum, 18CrMo4/1.7243 isn’t ideal for extremely high-temperature environments. For such applications, specialized heat-resistant steels are better suited.

- Carburization Process: The carburization process adds an extra step to the manufacturing process, increasing lead time and potentially cost compared to readily available steels. However, the performance benefits often outweigh this drawback for demanding applications.

Specifications, Sizes, and Grades

Chemical Composition (percentages by weight)

| Nguyên tố | Weight % |

|---|---|

| Carbon (C) | 0.15 – 0.21 |

| Silicon (Si) | Max 0.40 |

| Manganse (Mn) | 0.60 – 0.90 |

| Phốt pho (P) | Max 0.025 |

| Lưu huỳnh (S) | Max 0.035 |

| Crôm (Cr) | 0.90 – 1.20 |

| Molypden (Mo) | 0.15 – 0.25 |

| Đồng (Cu) | Up to 0.40 (optional) |

Standards:

- EN 10083-2 (European Standard)

- ASTM A29 (American Standard – equivalent grade: 4118)

- JIS G3141 (Japanese Standard – equivalent grade: SCM420)

Typical Sizes:

- Rounds: Diameters ranging from 5 mm to 200 mm (0.20 in to 7.87 in)

- Flats: Widths up to 300 mm (11.81 in) and thicknesses up to 100 mm (3.94 in)

- Forgings: Custom shapes and sizes are available

Grades:

There are no specific grades for 18CrMo4/1.7243. However, it can be supplied in different surface conditions, such as hot-rolled, annealed, normalized, and quenched and tempered.

Nhà cung cấp và Giá cả

18CrMo4/1.7243 is a widely available steel grade. Major steel mills and distributors around the world supply it in various forms. Pricing depends on factors like quantity, size, and surface condition.

Metal Powder Models (for Informational Purposes Only)

While the focus of this article is on wrought 18CrMo4/1.7243 alloy steel, it’s important to acknowledge the growing field of metal additive manufacturing (AM). Here are some metal powder models that share similar compositions and properties, but it’s important to note that they may not be exact matches and require separate qualification for AM processes:

- AM Powder 1: This could be a chromium-molybdenum pre-alloyed powder specifically designed for laser powder bed fusion (LPBF) with a composition close to 18CrMo4/1.7243. It might offer advantages like near-net-shape manufacturing and complex geometry creation.

- AM Powder 2: Another possibility is a mixture of elemental powders like iron, chromium, molybdenum, and carbon, allowing for precise control over the final chemistry. This approach might provide more flexibility in tailoring properties but could require additional steps like homogenization.

Remember, consulting with metal powder manufacturers and AM specialists is crucial when selecting a suitable powder for your specific application.

Câu hỏi thường gặp

Q: What are some alternatives to 18CrMo4/1.7243 alloy steel?

A: Depending on the specific requirements, several alternatives exist:

- For slightly lower strength applications: AISI 4140 steel offers a good balance of strength and machinability.

- For higher corrosion resistance: Stainless steels like 304 or 316 provide excellent corrosion resistance but might have lower strength compared to 18CrMo4/1.7243.

- For high-temperature applications: Heat-resistant steels like AISI 4130 or Inconel offer superior performance at elevated temperatures.

Q: Can 18CrMo4/1.7243 be welded?

A: Yes, 18CrMo4/1.7243 can be welded with proper procedures due to its good weldability. Preheating is recommended to minimize the risk of cracking. Consulting with a qualified welder is essential for achieving successful welds.

Q: How does the carburization process work?

A: Carburization involves exposing the steel to a carbon-rich atmosphere at high temperatures. This allows carbon to diffuse into the surface layer, creating a harder and more wear-resistant case. Common carburizing methods include pack carburizing, gas carburizing, and salt bath carburizing.

Q: What are the surface treatments available for 18CrMo4/1.7243 to improve corrosion resistance?

A: If corrosion resistance is a concern, various surface treatments can be applied to 18CrMo4/1.7243, such as:

- Painting: A cost-effective option for mild environments.

- Electroplating: Provides a thin layer of a corrosion-resistant metal like zinc or nickel.

- Phosphating: Creates a microscopic conversion layer that improves paint adhesion and offers some corrosion protection.

Kết luận

18CrMo4/1.7243 alloy steel stands out as a versatile and dependable material for various demanding applications. Its exceptional strength, good wear resistance, and weldability make it a valuable asset for engineers and manufacturers across industries. By understanding its properties, limitations, and available forms, you can make informed decisions about whether 18CrMo4/1.7243 is the right choice for your project.