Titanium Wire TA2 is a fascinating material widely recognized for its impressive properties and versatile applications. Whether you’re in aerospace, medical fields, or even consumer electronics, understanding the nuances of TA2 titanium wire can be incredibly beneficial. In this article, we’ll dive deep into the world of Titanium Wire TA2, exploring its composition, properties, uses, specifications, and even suppliers. So, why is Titanium Wire TA2 so important? Let’s find out together!

What Makes Titanium Wire TA2 Special?

Titanium TA2, also known as Grade 2 titanium, stands out due to its excellent corrosion resistance, high strength-to-weight ratio, and superb biocompatibility. It’s no wonder it’s so popular across various industries! Unlike some other metals, TA2 titanium wire is particularly useful in environments where both high strength and low weight are crucial.

Types of Titanium Wire TA2

Understanding the different models and specifications of Titanium Wire TA2 can help you choose the right type for your specific needs. Here are some of the common models you might encounter:

| Model | Composition | Properties | Uses |

|---|---|---|---|

| TA2-P | Pure Titanium (Grade 2) | Excellent corrosion resistance | Chemical processing, marine |

| TA2-A | Alloyed with minor metals | Improved ductility | Aerospace, medical implants |

| TA2-E | Enhanced for elasticity | High flexibility | Springs, medical devices |

| TA2-H | Hardened variant | Higher tensile strength | Industrial applications |

| TA2-T | Treated for toughness | High impact resistance | Sports equipment, tools |

| TA2-F | Fine wire for precision | High precision | Electronics, fine instrumentation |

| TA2-M | Machinable variant | Easier to machine | Custom parts, prototypes |

| TA2-B | Biocompatible | Safe for body use | Surgical tools, implants |

| TA2-C | Corrosion-resistant coating | Extra corrosion resistance | Underwater cables, pipelines |

| TA2-HT | High temperature variant | Withstands high temperatures | Aerospace, automotive engines |

Applications of Titanium Wire TA2

Titanium Wire TA2 is used in a plethora of applications due to its unique properties. Here’s a closer look at some of its common uses:

| Application Area | Description |

|---|---|

| Aerospace | Used in aircraft parts due to its strength and light weight |

| Medical Devices | Perfect for implants and surgical instruments |

| Marine Industry | Excellent for use in corrosive seawater environments |

| Chemical Processing | Resistant to corrosive chemicals and high temperatures |

| Sports Equipment | Lightweight yet strong, ideal for high-performance gear |

| Electronics | Used in precision components and high-end electronics |

| Automotive | Parts for high-performance vehicles and engines |

| Jewelry | Hypoallergenic and durable, great for body jewelry |

Specifications, Sizes, and Standards

Choosing the right specification and size is critical depending on your application. Here’s a detailed table to help you understand the various specifications of Titanium Wire TA2:

| Specification | Size Range | Standards |

|---|---|---|

| TA2-P | 0.1mm to 5mm diameter | ASTM B348, AMS 4928 |

| TA2-A | 0.2mm to 6mm diameter | ISO 5832-2, ASTM F67 |

| TA2-E | 0.15mm to 4mm diameter | ASTM B863, AMS 4951 |

| TA2-H | 0.5mm to 8mm diameter | ASTM B348, AMS 4928 |

| TA2-T | 0.3mm to 5mm diameter | ASTM B348, AMS 4928 |

| TA2-F | 0.05mm to 2mm diameter | ASTM B863 |

| TA2-M | 0.3mm to 6mm diameter | ASTM B348 |

| TA2-B | 0.1mm to 5mm diameter | ISO 5832-2, ASTM F67 |

| TA2-C | 0.2mm to 7mm diameter | ASTM B348, AMS 4928 |

| TA2-HT | 0.4mm to 4mm diameter | AMS 4928, AMS 4951 |

Suppliers and Pricing Details

Finding a reliable supplier is crucial for ensuring the quality of your Titanium Wire TA2. Here’s a list of some top suppliers along with their pricing details:

| Supplier | Pricing (per kg) | Location | Specialties |

|---|---|---|---|

| Titanium Industries | $120 – $150 | USA, Europe, Asia | Aerospace, medical, industrial |

| Supra Alloys | $110 – $140 | USA | High-performance applications |

| Advanced Titanium | $115 – $145 | Europe | Custom sizes and specifications |

| United Titanium | $125 – $155 | Global | Comprehensive material selection |

| Baoji Titanium | $105 – $135 | China | Competitive pricing, large volumes |

| Timet Titanium | $130 – $160 | USA, Europe | Aerospace and defense |

| VSMPO-AVISMA | $120 – $150 | Russia | High-quality, large production |

| Titanium Metal Supply | $110 – $145 | USA | Quick delivery, custom orders |

| Allegheny Technologies | $125 – $155 | Global | Advanced materials, R&D focus |

| Western Titanium | $115 – $140 | USA | Diverse industry applications |

Advantages of Titanium Wire TA2

When it comes to choosing materials, Titanium Wire TA2 has several advantages that make it a top choice in many industries. Here are some of the key benefits:

Corrosion Resistance

Titanium Wire TA2 is highly resistant to corrosion, even in harsh environments like seawater or chemical processing plants. This makes it an ideal choice for applications where durability is crucial.

High Strength-to-Weight Ratio

One of the most impressive features of Titanium Wire TA2 is its strength-to-weight ratio. It’s incredibly strong yet much lighter than steel, making it perfect for aerospace and automotive industries where every gram matters.

Biocompatibility

Titanium is biocompatible, meaning it’s not harmful to living tissue. This property makes TA2 titanium wire an excellent material for medical implants and devices.

Versatility

Whether you need it for industrial applications, medical devices, or sports equipment, Titanium Wire TA2 is versatile enough to meet the demands of various fields.

High Temperature Resistance

Titanium Wire TA2 can withstand high temperatures, which is essential for applications in aerospace and automotive industries where materials are exposed to extreme conditions.

Disadvantages of Titanium Wire TA2

While Titanium Wire TA2 has numerous benefits, it’s also important to be aware of its drawbacks. Here are some of the limitations:

Cost

Titanium Wire TA2 is more expensive compared to other metals like aluminum or steel. This can be a significant factor if you’re working with a tight budget.

Machinability

Working with Titanium Wire TA2 can be challenging due to its toughness. Specialized tools and techniques are often required, which can increase manufacturing costs.

Availability

Depending on your location, finding a reliable supplier for Titanium Wire TA2 might be challenging. This can lead to longer lead times and higher shipping costs.

Brittleness at Low Temperatures

At very low temperatures, Titanium Wire TA2 can become brittle. This is something to consider if your application involves extreme cold conditions.

Comparing Titanium Wire TA2 with Other Metals

When choosing a material for your project, it’s helpful to compare Titanium Wire TA2 with other commonly used metals. Here’s a comparison table highlighting the differences:

| Parameter | Titanium Wire TA2 | Stainless Steel | Aluminum |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Moderate |

| Strength-to-Weight Ratio | High | Moderate | Low |

| Biocompatibility | Excellent | Good | Poor |

| Cost | High | Moderate | Low |

| Machinability | Difficult | Moderate | Easy |

| Availability | Moderate | High | High |

| Brittleness at Low Temps | Moderate | Low | High |

| Applications | Aerospace, Medical | Industrial, Consumer | Automotive, Consumer |

FAQs

What is Titanium Wire TA2?

Titanium Wire TA2 is a type of commercially pure titanium alloy designated as Grade 2 according to ASTM standards. It consists mainly of titanium and small amounts of oxygen, nitrogen, carbon, hydrogen, and iron.

What are the properties of Titanium Wire TA2?

Titanium Wire TA2 exhibits excellent corrosion resistance, high strength-to-weight ratio, good formability, and biocompatibility. It has low density, high melting point, and is non-magnetic.

What are the common applications of Titanium Wire TA2?

Titanium Wire TA2 is widely used in various industries such as aerospace, medical, chemical processing, marine, automotive, and sports equipment. It is utilized in applications requiring high corrosion resistance, lightweight construction, and biocompatibility, such as surgical implants, aircraft components, and marine equipment.

How is Titanium Wire TA2 manufactured?

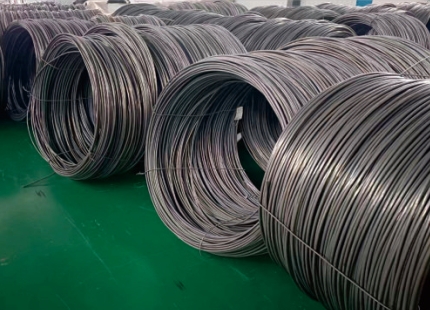

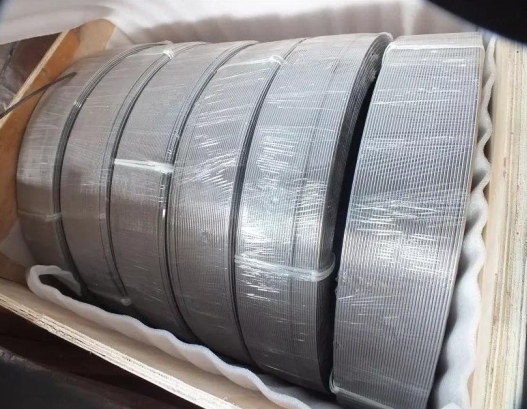

Titanium Wire TA2 is typically produced through the process of hot rolling or cold drawing from titanium ingots. These processes help to achieve the desired diameter, surface finish, and mechanical properties of the wire.

What are the available sizes and forms of Titanium Wire TA2?

Titanium Wire TA2 is available in various diameters ranging from a fraction of a millimeter to several millimeters. It can be supplied in straight lengths, coils, or spools, depending on the requirements of the application.