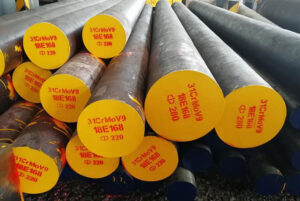

When it comes to selecting materials for high-performance applications, few alloys match the versatility and robustness of Super 316 Stainless Steel. This advanced material is known for its exceptional corrosion resistance, durability, and strength, making it a preferred choice in various industries, from marine to chemical processing. In this comprehensive guide, we’ll delve into the details of Super 316 Stainless Steel, covering its chemical composition, applications, mechanical properties, heat treatment processes, and more. So, buckle up and get ready to explore this fascinating material in depth!

Overview of Super 316 Stainless Steel

Super 316 Stainless Steel is an enhanced version of the conventional 316 stainless steel, boasting improved resistance to corrosion and enhanced mechanical properties. This makes it an ideal candidate for demanding environments where standard 316 might fall short. Let’s break down what makes Super 316 Stainless Steel stand out:

- Superior Corrosion Resistance: Thanks to its high molybdenum content, Super 316 Stainless Steel offers better resistance to pitting and crevice corrosion, especially in chloride environments.

- Enhanced Mechanical Properties: This alloy is stronger and more durable than regular 316 stainless steel, making it suitable for high-stress applications.

- Versatile Applications: From marine equipment to chemical processing plants, Super 316 Stainless Steel is used in a wide range of industries due to its reliability and performance.

Chemical Composition of Super 316 Stainless Steel

The unique properties of Super 316 Stainless Steel stem from its specific chemical makeup. Here’s a detailed look at its composition:

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Nitrogen (N) | ≤ 0.1 |

| Iron (Fe) | Balance |

The high chromium and nickel content contribute to the alloy’s outstanding corrosion resistance, while the molybdenum enhances its performance in harsh environments.

Applications of Super 316 Stainless Steel

Super 316 Stainless Steel’s remarkable properties make it a go-to material for many critical applications. Here’s a breakdown of where you might find this alloy in use:

| Industry | Application |

|---|---|

| Marine | Boat fittings, shipbuilding components, coastal structures |

| Chemical Processing | Storage tanks, piping systems, heat exchangers |

| Food and Beverage | Processing equipment, containers, kitchen appliances |

| Medical | Surgical instruments, implants, medical devices |

| Oil and Gas | Offshore platforms, pipelines, valves |

| Aerospace | Aircraft components, aerospace fasteners |

Each application benefits from the material’s high resistance to corrosion and excellent mechanical properties, ensuring longevity and reliability.

Mechanical Properties of Super 316 Stainless Steel

Understanding the mechanical properties of Super 316 Stainless Steel is crucial for selecting the right material for your needs. Here’s an overview:

| Property | Value |

|---|---|

| Tensile Strength | 515 MPa (minimum) |

| Yield Strength | 205 MPa (minimum) |

| Elongation | 40% (minimum) |

| Hardness (Brinell) | 217 HB |

These values highlight the material’s strength and ductility, making it suitable for various high-stress applications.

Heat Treatment of Super 316 Stainless Steel

Heat treatment processes can significantly impact the performance of Super 316 Stainless Steel. Here’s a guide to the typical heat treatment processes used:

| Process | Temperature Range | Cooling Method |

|---|---|---|

| Annealing | 1010°C – 1120°C | Rapid cooling in air or water |

| Stress Relieving | 450°C – 600°C | Air cooling |

| Solution Treatment | 1040°C – 1120°C | Water quenching |

These processes help enhance the material’s mechanical properties and corrosion resistance, ensuring optimal performance in various applications.

Suppliers and Pricing Details of Super 316 Stainless Steel

Finding the right supplier for Super 316 Stainless Steel is essential for obtaining high-quality material. Here’s a look at some of the leading suppliers and typical pricing details:

| Supplier | Region | Price Range (per kg) |

|---|---|---|

| Supplier A | North America | $5 – $7 |

| Supplier B | Europe | €4 – €6 |

| Supplier C | Asia | $3 – $5 |

| Supplier D | Australia | AUD 6 – AUD 8 |

Prices can vary based on the quantity purchased, specific alloy grade, and market conditions.

Advantages and Disadvantages of Super 316 Stainless Steel

Like any material, Super 316 Stainless Steel has its pros and cons. Here’s a comparison to help you make an informed decision:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Corrosion Resistance | Excellent, especially in chloride environments | Higher cost compared to standard 316 stainless steel |

| Mechanical Properties | High strength and durability | May require special welding techniques |

| Versatility | Suitable for a wide range of applications | Limited availability in some regions |

| Longevity | Long-lasting performance | Heavier than some alternative materials |

This comparison highlights why Super 316 Stainless Steel is often chosen despite its higher cost, thanks to its superior performance and durability.

FAQ

What makes Super 316 Stainless Steel different from regular 316 stainless steel?

Super 316 Stainless Steel has enhanced properties, particularly in terms of corrosion resistance and mechanical strength, due to its higher molybdenum content and refined chemical composition.

Can Super 316 Stainless Steel be welded?

Yes, it can be welded, but it may require specific techniques and fillers to ensure optimal weld quality and prevent sensitization.

Is Super 316 Stainless Steel suitable for high-temperature applications?

Yes, it performs well in high-temperature environments, thanks to its excellent mechanical properties and stability.

How does Super 316 Stainless Steel compare to other stainless steels?

Compared to standard 316 stainless steel, Super 316 offers better corrosion resistance and strength. Compared to 304 stainless steel, it provides superior performance in harsh environments but at a higher cost.

Where can I buy Super 316 Stainless Steel?

Several suppliers worldwide offer Super 316 Stainless Steel, including those in North America, Europe, Asia, and Australia. Prices vary based on the supplier and region.

Conclusion

Super 316 Stainless Steel stands out as a premium material choice for applications requiring exceptional corrosion resistance and mechanical properties. Its versatility makes it suitable for a wide range of industries, from marine to aerospace. While it may come at a higher cost, the performance benefits often justify the investment. Whether you’re in the market for high-quality stainless steel for demanding environments or simply looking to understand more about this remarkable alloy, Super 316 Stainless Steel is a material worth considering.