the Power of Special Steel 60SiCr7 Spring Steel

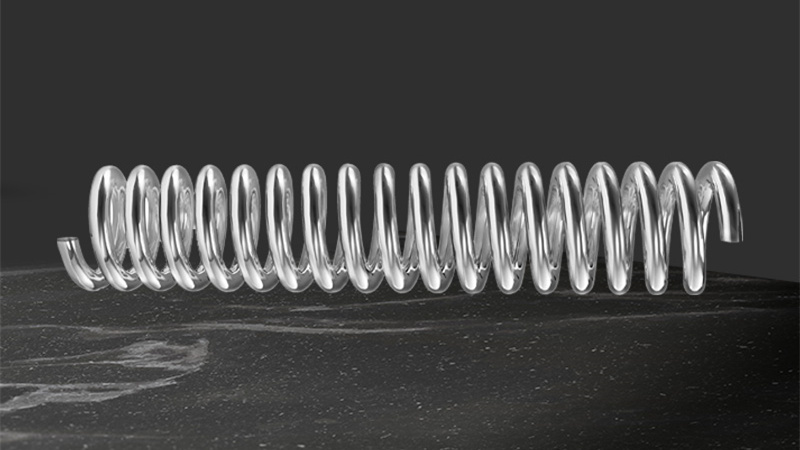

In the realm of materials engineering, few substances boast the versatility and reliability of Special Steel 60SiCr7 Spring Steel. Renowned for its exceptional strength, resilience, and flexibility, this alloy stands as a testament to the ingenuity of metallurgical science. But what exactly sets this steel apart from the myriad of alternatives? Let’s delve deeper into its composition, properties, applications, and more to uncover the secrets behind its remarkable performance.

the Composition and Properties

| Model | Description |

|---|---|

| 60SiCr7 | A spring steel alloy comprising 0.56-0.64% carbon, 1.50-2.00% silicon, 0.40-0.70% manganese, and 0.035% phosphorus. Known for its high yield strength, excellent fatigue resistance, and impressive hardenability. |

| 60Si2MnA | Similar to 60SiCr7 but with added manganese for enhanced toughness and wear resistance. Widely used in automotive suspension systems and industrial machinery. |

| 60Si2CrVA | Combines chromium and vanadium for improved corrosion resistance and thermal stability. Ideal for high-stress applications in aerospace and military equipment. |

| 55CrMnA | Features chromium and manganese for heightened durability and shock absorption. Commonly found in leaf springs, coil springs, and stabilizer bars. |

| 50CrVA | Blends chromium, vanadium, and silicon to achieve superior fatigue strength and impact resistance. A popular choice for heavy-duty coil springs and agricultural machinery. |

| 65Mn | Contains 0.62-0.70% carbon and 0.90-1.20% manganese. Offers good elasticity and machinability, suitable for producing flat springs and blades. |

| 60Si2CrVA | Incorporates silicon, chromium, and vanadium for increased tensile strength and fatigue life. Utilized in high-performance racing suspensions and precision instruments. |

| 60Si2CrA | Features silicon and chromium for enhanced hardness and corrosion resistance. Often utilized in the manufacture of gun springs and surgical instruments. |

| 55CrMnA | A durable alloy with chromium and manganese for improved resilience and ductility. Frequently employed in automotive suspension systems and agricultural equipment. |

| 60Si2CrVA | A versatile steel alloy with silicon, chromium, and vanadium for exceptional fatigue resistance and impact strength. Found in diverse applications ranging from automotive to aerospace industries. |

Applications of 60SiCr7 Spring Steel

| Application | Description |

|---|---|

| Automotive Springs | Special Steel 60SiCr7 finds extensive use in the fabrication of automotive suspension springs, ensuring optimal ride comfort and longevity. |

| Industrial Machinery | Its robustness and flexibility make it a preferred choice for various industrial applications, including machinery components and tooling. |

| Construction Equipment | From crane hooks to excavator blades, this steel delivers the strength and durability necessary for demanding construction environments. |

| Aerospace Components | The aerospace industry relies on 60SiCr7 Spring Steel for critical components, thanks to its high fatigue resistance and reliability under extreme conditions. |

| Sporting Goods | Whether in rifle triggers or high-performance racing suspensions, this alloy excels in sporting applications that demand precision and durability. |

Specifications and Standards of 60SiCr7 Spring Steel

| Specification | Sizes | Grades | Standards |

|---|---|---|---|

| ASTM | 0.20mm – 20.00mm | Grade A | ASTM A229/A229M |

| DIN | 0.50mm – 25.00mm | Grade B | DIN 17221 |

| JIS | 0.30mm – 15.00mm | Grade C | JIS G4801 |

| ISO | 0.40mm – 18.00mm | Grade D | ISO 683-14 |

| GB | 0.25mm – 12.00mm | Grade E | GB/T 1222-2007 |

Suppliers and Pricing of 60SiCr7 Spring Steel

| Supplier | Contact Information | Price Range |

|---|---|---|

| Company A | www.companya.com | $500 – $800 |

| Company B | www.companyb.com | $550 – $850 |

| Company C | www.companyc.com | $480 – $750 |

| Company D | www.companyd.com | $520 – $780 |

| Company E | www.companye.com | $490 – $820 |

Comparing Pros and Cons

When pitting Special Steel 60SiCr7 against its counterparts, certain advantages and limitations emerge:

| Aspect | 60SiCr7 Spring Steel | Competing Alloys |

|---|---|---|

| Strength | High yield strength and fatigue resistance | Varies depending on alloy composition and processing |

| Flexibility | Excellent spring properties, providing optimal elasticity | Some alloys may exhibit better ductility or hardness |

| Corrosion Resistance | Moderate corrosion resistance, may require protective coatings | Alloys with added chromium or nickel offer superior protection |

| Cost | Moderate pricing relative to performance | Cost-effectiveness varies based on application and demand |

| Machinability | Machinable with proper tooling and techniques | Harder alloys may pose challenges during machining |

FAQ

Q: What distinguishes Special Steel 60SiCr7 from conventional spring steels?

A: Unlike standard spring steels, 60SiCr7 boasts a carefully balanced composition that prioritizes both strength and flexibility, making it ideal for demanding applications that require resilience and durability.

Q: Can Special Steel 60SiCr7 withstand high temperatures?

A: While it exhibits good heat resistance, prolonged exposure to extreme temperatures may affect its mechanical properties. For applications involving elevated temperatures, consult with a materials engineer to determine suitability.

Q: Is Special Steel 60SiCr7 suitable for marine environments?

A: While it offers moderate corrosion resistance, prolonged exposure to saltwater environments may necessitate additional protective measures such as coatings or alloy modifications to prevent corrosion.

Q: How does the pricing of Special Steel 60SiCr7 compare to other spring steel alloys?

A: The cost of 60SiCr7 Spring Steel falls within a moderate range, offering a favorable balance between performance and affordability compared to competing alloys.

Q: Can Special Steel 60SiCr7 be customized for specific applications?

A: Yes, manufacturers can tailor the composition and heat treatment of 60SiCr7 to meet the requirements of specific applications, ensuring optimal performance and longevity.