Overview

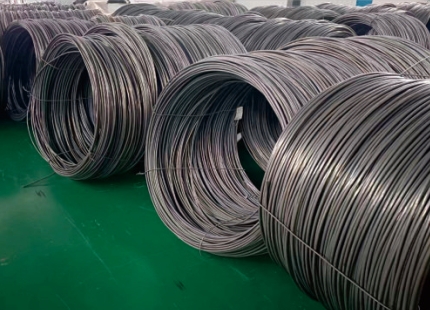

In the ever-evolving world of industrial materials, titanium wire TA2 stands out as a remarkable innovation. This advanced titanium alloy combines exceptional strength, corrosion resistance, and temperature tolerance, making it an indispensable choice for a wide range of demanding applications. From aerospace to automotive, medical to chemical processing, titanium wire TA2 is revolutionizing industries with its unparalleled performance and versatility. Join us as we explore the intricacies of this game-changing material, unraveling its composition, properties, and diverse applications that continue to push the boundaries of what’s possible.

Composition and Unique Properties

At the heart of titanium wire TA2’s exceptional capabilities lies its carefully engineered composition. This alpha-beta titanium alloy is meticulously crafted by combining titanium with strategic additions of aluminum, vanadium, and other elements to achieve a superior blend of properties. Let’s delve into the key characteristics that set titanium wire TA2 apart:

- Unrivaled Strength: Titanium wire TA2 boasts an incredibly high strength-to-weight ratio, surpassing many conventional materials. This remarkable strength is derived from the synergistic effects of its alloying elements, allowing it to withstand immense loads and stresses without compromising its lightweight nature.

- Corrosion Resistance Extraordinaire: Corrosion is no match for titanium wire TA2. This alloy forms a tenacious, self-healing oxide layer on its surface, acting as an impenetrable barrier against various corrosive environments, including harsh chemicals, saltwater, and atmospheric conditions.

- Thermal Stability Unleashed: Whether subjected to scorching temperatures or extreme cold, titanium wire TA2 maintains its structural integrity and performance. This thermal stability makes it an ideal choice for applications involving high-temperature processes, jet engines, or cryogenic environments.

- Biocompatibility Redefined: Titanium wire TA2 is highly biocompatible, minimizing the risk of adverse reactions or tissue rejection. This property has propelled its widespread adoption in the medical field, enabling the development of advanced implants, surgical instruments, and prosthetic devices.

Applications

The remarkable properties of titanium wire TA2 have unlocked a world of possibilities across a multitude of industries. From cutting-edge aerospace components to life-saving medical devices, this versatile material is reshaping the boundaries of what’s achievable. Let’s explore some of its most prominent applications:

- Aerospace Ingenuity: In the aerospace industry, where weight savings and high-temperature performance are paramount, titanium wire TA2 has become an essential component. It is used in the construction of aircraft engines, airframes, and critical structural components, contributing to improved fuel efficiency, reduced emissions, and enhanced safety.

- Automotive Excellence: The automotive industry is constantly seeking lightweight and high-strength materials to improve vehicle performance and efficiency. Titanium wire TA2 has found its way into various automotive applications, such as suspension components, exhaust systems, and high-performance engine parts, delivering uncompromising performance and durability.

- Medical Marvels: The biocompatibility and corrosion resistance of titanium wire TA2 have revolutionized the medical field. It is widely used in surgical instruments, implants, orthodontic wires, and prosthetic devices, ensuring safe and effective treatments while promoting faster healing and recovery.

- Chemical Processing Prowess: In the chemical processing industry, where harsh environments and corrosive substances are the norm, titanium wire TA2 has proven to be an invaluable asset. It is utilized in the construction of piping systems, heat exchangers, and reaction vessels, enabling safe and efficient handling of aggressive chemicals.

- Energy Exploration Resilience: The energy sector, particularly in offshore oil and gas exploration, demands materials that can withstand the harsh marine environment. Titanium wire TA2’s exceptional corrosion resistance and strength make it an ideal choice for offshore platforms, subsea equipment, and piping systems.

- Sporting Goods Innovation: In the world of sports and recreation, where performance and durability are paramount, titanium wire TA2 has found its way into high-end equipment. From lightweight and ultra-strong bicycle frames to premium golf clubs and tennis rackets, this alloy is revolutionizing the way athletes push their limits.

Manufacturing Processes and Quality Control

Producing titanium wire TA2 requires advanced manufacturing techniques and stringent quality control measures to ensure consistent performance and reliability. Here’s a glimpse into the processes involved:

- Vacuum Arc Remelting (VAR): This specialized melting process is used to produce high-purity titanium ingots by melting and solidifying the alloy in a vacuum environment, minimizing impurities and ensuring consistent chemical composition.

- Hot Extrusion and Cold Drawing: Heated titanium billets are extruded through dies to form wire rods, which are then subjected to a series of cold drawing steps to reduce the diameter and enhance the wire’s strength and uniformity.

- Surface Treatments: Titanium wire TA2 can undergo various surface treatments, such as anodizing, nitriding, or coating, to enhance specific properties like wear resistance, lubricity, or electrical conductivity, tailoring it for specialized applications.

- Rigorous Testing and Inspection: Throughout the manufacturing process, titanium wire TA2 undergoes a comprehensive range of tests and inspections to ensure compliance with stringent quality standards. These include mechanical testing, metallographic analysis, chemical composition verification, and non-destructive testing techniques like ultrasonic inspection and eddy current testing.

Environmental Impact and Sustainability

In an era where environmental consciousness is of paramount importance, titanium wire TA2 stands out as an eco-friendly choice. Titanium is a highly recyclable material, and the manufacturing processes involved in producing titanium wire TA2 have a relatively low environmental impact compared to other metals. Additionally, the exceptional corrosion resistance and long service life of this alloy contribute to reduced waste and energy consumption, aligning with sustainable practices and promoting a greener future.

Cutting-Edge Innovations and Future Developments

The realm of titanium wire TA2 is constantly evolving, driven by the relentless pursuit of innovation and technological advancements. Material scientists and researchers are continuously exploring new frontiers, pushing the boundaries of what’s possible with this remarkable alloy. Some of the exciting areas of focus include:

- Improved Strength and Ductility: Ongoing research aims to develop titanium alloys with even higher strength and ductility, enabling the production of wires that can withstand greater loads and deformations without compromising their structural integrity.

- Enhanced Corrosion Resistance: Efforts are underway to develop titanium alloys with superior corrosion resistance, expanding their applications in highly corrosive environments, such as offshore oil and gas operations or chemical processing.

- Additive Manufacturing Integration: The integration of additive manufacturing techniques, such as wire-based 3D printing, could revolutionize the production of complex titanium wire components, opening up new possibilities in various industries.

- Surface Engineering Advancements: Advancements in surface engineering techniques, such as plasma nitriding or ceramic coatings, could further improve the wear resistance, lubricity, and functional properties of titanium wire TA2, tailoring it for specialized applications.

- Alloy Optimization: Ongoing research into alloy compositions and heat treatments aims to further optimize the properties of titanium wire TA2, potentially unlocking new applications and pushing the boundaries of performance.

Frequently Asked Questions (FAQs)

- What makes titanium wire TA2 superior to other titanium alloys? Titanium wire TA2 stands out due to its unique combination of high strength, corrosion resistance, and temperature tolerance. This balanced set of properties makes it suitable for a wide range of demanding applications where other alloys may fall short.

- Is titanium wire TA2 expensive compared to other materials? While titanium wire TA2 is relatively more expensive than some conventional materials, its exceptional performance and longevity often justify the initial investment, making it a cost-effective solution in the long run, especially for critical applications.

- Can titanium wire TA2 be welded or joined? Yes, titanium wire TA2 can be welded or joined using various techniques, such as gas tungsten arc welding (GTAW), laser beam welding, or friction stir welding. However, specific procedures and precautions must be followed to ensure proper joining and prevent contamination or degradation of the material’s properties.