IMI829 titanium alloy wire sits in a select group of high‑temperature titanium materials engineered for demanding aerospace and industrial service. It combines elevated‑temperature strength, good fatigue resistance and oxidation performance with the weight savings of titanium, making it attractive wherever every gram matters but reliability is non‑negotiable. If you are evaluating IMI829 titanium alloy wire for a new program or as part of a re‑qualification, sharing your target specs, standards, and volumes early will allow a specialist supplier to propose the optimal grade, condition, and packaging with a clear cost and lead‑time profile.

IMI829 Titanium Alloy Wire Overview and Key Properties

IMI829 titanium alloy wire is a high‑temperature titanium alloy typically used where continuous service or transient excursions to elevated temperatures are expected, but where nickel‑based superalloys would impose an unacceptable weight penalty. Compared with conventional aerospace titanium grades, IMI829 is designed to retain strength, creep resistance and structural stability at higher temperatures, while maintaining good specific strength and corrosion resistance.

In wire form, IMI829 offers a fine balance of tensile strength, ductility, and fatigue performance, allowing it to serve in springs, fasteners, control cables, and structural or attachment wire elements. The alloy’s relatively low density compared to steels and nickel alloys enables designers to reduce mass while preserving load‑carrying capability, which is especially valuable in rotating and flight‑critical components. IMI829 titanium alloy wire also offers good oxidation resistance in hot air and exhaust environments, supporting use near engines and high‑temperature ducts.

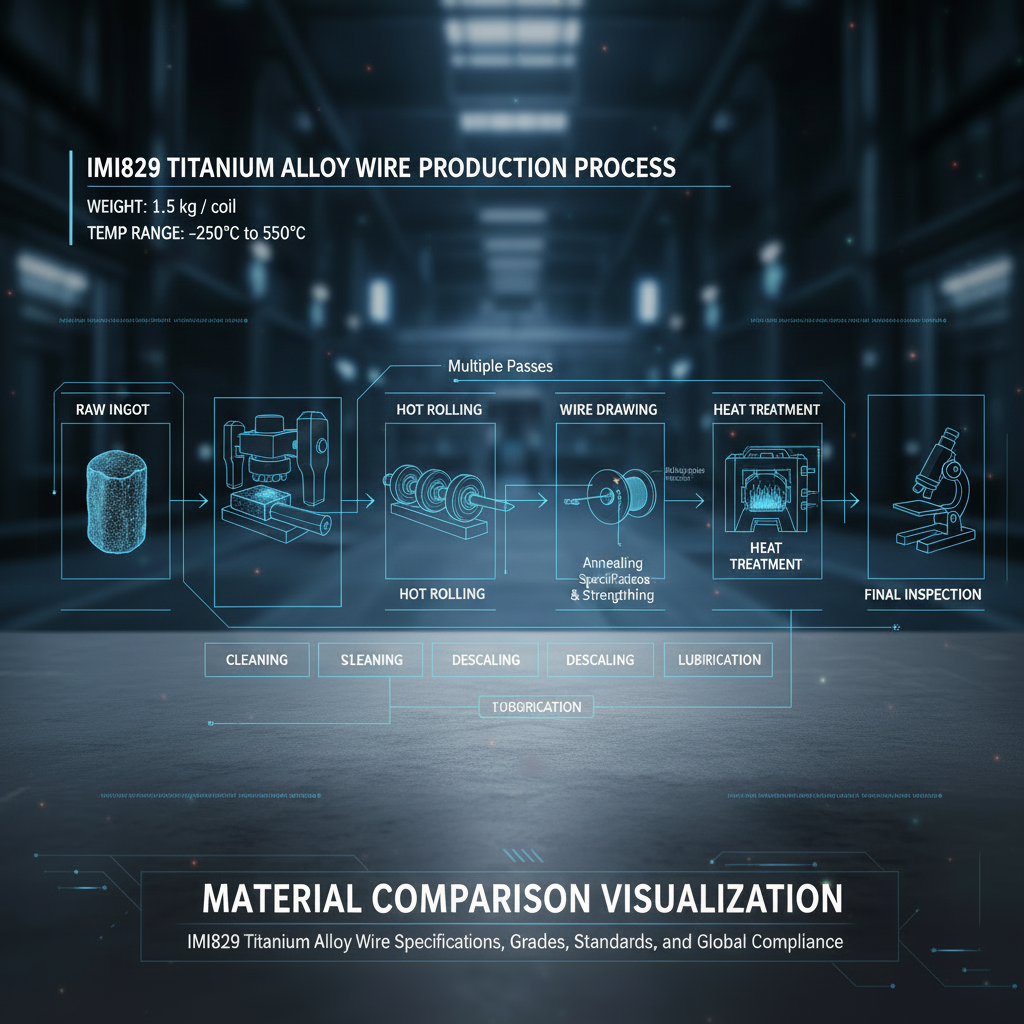

From a processing standpoint, IMI829 wire can be supplied in a range of cold‑work and heat‑treatment conditions, from relatively soft, formable tempers for intricate bending, coiling or swaging, through to higher‑strength, stress‑relieved tempers for structural applications. Surface finish, cleanliness and dimensional tolerance are critical, since many end uses demand excellent fatigue performance and low defect populations. Experienced manufacturers use closely controlled drawing, straightening and finishing operations to achieve the required surface quality and mechanical uniformity.

Chemical Composition and Metallurgical Profile of IMI829 Wire

The chemical composition of IMI829 titanium alloy wire is optimized to deliver high‑temperature strength and stability through a balanced mix of alpha‑ and beta‑stabilizing elements. While exact ranges are defined in proprietary or standards documents, IMI829 typically includes aluminum as a primary alpha stabilizer to increase strength and creep resistance, with one or more beta‑stabilizing additions (such as molybdenum or vanadium family elements). Trace interstitials like oxygen, nitrogen, carbon and hydrogen are tightly controlled because they strongly affect ductility, fracture toughness, and fatigue life.

In its wire form, IMI829 generally exhibits a fine alpha‑beta microstructure, developed through carefully chosen hot‑working and subsequent heat‑treatment schedules. The balance between equiaxed alpha grains and retained beta, as well as the distribution of secondary alpha within prior beta grains, influences high‑temperature capability and fatigue response. For critical aerospace or energy applications, consistent microstructure along the wire length is essential, which drives rigorous control of billet conversion, drawing reduction ratios, intermediate anneals, and final heat treatments.

Impurity control is another pillar of the metallurgical profile of IMI829 wire. Low inclusion content, excellent cleanliness, and absence of alpha‑case or decarburization are key to avoiding crack initiation under cyclic loading. Wire manufacturers typically deploy vacuum melting practices (such as VAR or similar) combined with stringent forging and inspection controls to ensure homogeneous composition and microstructural integrity from core to surface.

Mechanical and High-Temperature Performance Data for IMI829 Wire

Mechanical properties for IMI829 titanium alloy wire depend on diameter, condition, and test temperature, but the overarching theme is retention of useful strength and fatigue performance beyond the limits of many standard titanium grades. In room‑temperature testing, IMI829 wire generally offers high tensile strength and good yield strength combined with sufficient elongation to allow forming and assembly operations, particularly in softer or solution‑treated tempers.

As service temperature rises, tensile properties inevitably drop, but IMI829 is engineered so that its creep resistance and time‑dependent deformation remain within acceptable bounds over long exposures. For components in hot zones—such as near turbine casings or exhaust structures—designers often rely on high‑temperature rupture and creep curves in conjunction with safety factors tailored to mission life. In fatigue‑critical uses, such as springs and fasteners, the alloy’s fatigue strength is heavily influenced by surface condition and microcleanliness, making high‑quality drawing, polishing, and handling practices essential.

In more severe applications, designers may examine low‑cycle fatigue, crack‑growth behavior, and notch sensitivity. IMI829’s alpha‑beta structure can be tuned to provide a workable compromise between crack‑growth resistance and high‑temperature strength. Stress‑relieving or aging treatments can reduce residual stress from drawing, which helps maintain dimensional stability and fatigue life. When reviewing data sheets from different suppliers, it is important to confirm that property data correspond to the intended diameter range, heat treatment, and surface condition, as each of these can materially affect the usable design allowables.

IMI829 Titanium Alloy Wire Grades, Conditions and Tempers

IMI829 titanium alloy wire is typically offered in a variety of grades and conditions, each targeting a different mix of formability, strength, and stability. “Grades” may refer to subtle composition windows or to distinct specifications that define the permissible ranges of elements and mechanical properties. Within a given grade, the wire can be supplied in solution‑treated, solution‑treated and aged, fully annealed, cold‑worked, or cold‑worked and stress‑relieved versions.

For forming‑intensive operations such as tight‑radius coiling, swaging, or complex routing, designers often specify an annealed or lightly cold‑worked condition that provides higher elongation and lower yield strength. This facilitates bending without cracking and allows for minor re‑work during assembly. Once formed, components can sometimes be given a subsequent aging treatment to increase strength, provided the customer’s specifications and part geometry permit.

High‑strength applications, including structural fasteners or high‑load springs, may favor cold‑worked and aged or stress‑relieved tempers. These offer higher yield and tensile strength, and can improve dimensional stability under sustained loads, but usually at the expense of some ductility and formability. In smaller diameters, increased cold work can also raise strength, though it requires careful balance to avoid excessive residual stresses that could impair fatigue performance or cause distortion after machining.

A useful rule of thumb is to define the required forming operations first, then match the IMI829 wire condition to that process, and finally ensure the resulting properties in the finished geometry still meet design needs. Collaboration between OEM design teams and wire manufacturers is critical to selecting the optimal temper and to defining acceptable property windows and in‑process heat‑treatment steps.

International Standards and Designations for IMI829 Titanium Wire

Although IMI829 is often recognized by its proprietary or historical designation, it can also be referenced against international titanium wire standards where equivalents or analogous grades exist. Depending on the region and application, IMI829 titanium alloy wire may be specified under aerospace material specifications, national standards, or large OEM internal standards that define chemistry, mechanical properties, and quality requirements.

In many aerospace programs, specifications similar in structure to AMS, EN or ISO titanium wire standards are used to define baseline requirements, supplemented by program‑specific addenda for inspection, fatigue controls, and heat‑treatment restrictions. Where a direct one‑to‑one cross‑reference does not exist, engineers may use property and composition comparisons to map IMI829 to the nearest standard grade, ensuring that substitution does not compromise performance.

It is essential for procurement and quality teams to align the purchasing specification with the applicable international standard or OEM document number. This ensures that critical details—such as lot definition, permissible heat‑treatment ranges, surface condition limits, NDT requirements, and mechanical test directions—are properly flowed down to the wire manufacturer. A well‑constructed material specification simplifies global qualification and supports consistent use of IMI829 titanium wire across multiple manufacturing sites.

IMI829 Wire Compliance with Aerospace and Global Quality Systems

Compliance with aerospace and global quality systems is a non‑negotiable requirement for IMI829 titanium alloy wire used in flight‑critical or safety‑critical components. Typical expectations include certification to recognized quality management standards such as AS/EN 9100 for aerospace and ISO 9001 for broader industrial sectors, along with approvals from major OEMs. These frameworks ensure that material traceability, process control, risk management, and corrective action systems are robust.

For IMI829 wire, compliance means every heat and lot can be traced from melt through billet conversion, drawing, heat treatment, inspection, and final delivery. Mill test reports and certificates of conformance should summarize chemical analysis, mechanical tests, heat‑treatment conditions, dimensions, and inspection results, all linked to unique lot identifiers. In many aerospace applications, additional controls such as process frozen plans, periodic audits, and statistical process control are layered on top of standard procedures.

When qualifying a new supplier for IMI829 wire, OEMs frequently conduct on‑site assessments to confirm that the producer’s quality system is mature and aligned with program needs. Items such as calibration systems, training records, document control, and nonconformance management are evaluated alongside technical capability. For global compliance, it is also important that export‑control and regulatory requirements are understood and correctly managed, particularly when material will cross borders or enter tightly controlled applications.

Available IMI829 Titanium Wire Diameters, Tolerances and Packaging

IMI829 titanium alloy wire is usually available across a wide range of diameters, from fine wires used in small fasteners, pins, or springs, through to larger diameters that can be machined or forged into more substantial components. The specific size ranges depend on the manufacturer’s equipment and drawing practices, but aerospace users commonly source wire in both coil and straight‑length forms to match their fabrication processes.

Tolerances for IMI829 wire are typically defined in relevant standards or purchase specifications and can be quite tight for precision components. Diameter tolerances may be specified as symmetric or asymmetric bands, depending on whether the design is more sensitive to undersize or oversize conditions. In addition to diameter, straightness, ovality, and surface finish must be controlled, with inspection regimes often including laser micrometry, visual inspection, and surface roughness checks. Where fatigue is critical, additional surface integrity requirements may be applied.

Packaging options for IMI829 titanium wire are chosen to protect surface quality and maintain traceability from mill to point of use. Coiled wire may be supplied on spools or reels, individually wrapped and labeled with heat and lot information. Straight lengths are often bundled, end‑capped, or placed in protective sleeves or tubes. For export shipments or long‑term storage, corrosion‑inhibiting wraps and desiccant can be used even though titanium itself is corrosion‑resistant, primarily to protect any labels or accessory components. When requesting quotations, specifying preferred coil sizes, spool types, or bundle lengths helps minimize waste and streamline your internal handling.

Comparison of IMI829 Wire with Other High-Temperature Titanium Alloys

When selecting a high‑temperature material, engineers often compare IMI829 titanium alloy wire to other elevated‑temperature titanium grades or even to nickel‑based superalloys and heat‑resistant steels. IMI829 is typically positioned to offer higher temperature capability than many conventional aerospace titaniums while remaining significantly lighter than nickel alloys. This provides a compelling option where both thermal resistance and weight reduction must be balanced.

From a practical standpoint, the choice between IMI829 and alternative titanium alloys may hinge on available standards, qualification history, and specific property targets such as creep resistance, fatigue performance, or oxidation behavior. Some alternative titanium alloys may offer slightly higher temperature windows but at the cost of more challenging processing or reduced ductility, while others may be easier to form but provide less margin at the upper end of the temperature range.

The comparison is often summarized in terms of operating temperature envelope, density, relative strength, and typical application examples, as shown below.

| Alloy / Material | Typical Operating Temperature Envelope | Relative Density | Notes on IMI829 Titanium Alloy Wire vs. Alternatives |

|---|---|---|---|

| IMI829 titanium alloy wire | High for titanium alloys; suited to hot aerospace zones | Low (titanium range) | Balances elevated‑temperature strength, weight savings, and fatigue performance. |

| Conventional aerospace Ti alloy | Moderate temperature capability | Low (titanium range) | Easier to qualify but may not offer sufficient high‑temperature margin in some designs. |

| High‑temperature Ti alloy variant | Higher temperature capability | Low (titanium range) | May extend temperature range but can be more demanding in processing and availability. |

| Nickel‑based superalloy wire | Very high temperature capability | High | Superior thermal limits but with major weight penalty; used when temperature dominates all other factors. |

| Heat‑resistant steel wire | Moderate‑to‑high temperature capability | Medium‑to‑high | Cost‑effective and strong but heavier and potentially less corrosion‑resistant than titanium. |

This comparison highlights why IMI829 is attractive when designers need to push temperature capability beyond standard titanium, yet cannot accept the mass increase of nickel alloys or steels. In practice, final selection should be backed by test data and, where possible, by service history in similar operating environments.

Recommended Applications and Design Guidelines for IMI829 Wire

Typical applications for IMI829 titanium alloy wire include engine‑adjacent hardware, hot‑zone fasteners, springs and retaining rings, wire forms in exhaust and nacelle systems, and structural or control elements where elevated temperatures are encountered. Beyond aerospace, IMI829 may also be specified in high‑performance industrial equipment, energy systems, or motorsport components that operate at elevated temperatures and are weight‑sensitive.

When designing with IMI829 wire, a practical guideline is to start with the anticipated worst‑case service temperature profile, including transient peaks and dwell periods, and then select the appropriate material condition and diameter based on allowable stresses derived from test data. Designers should also account for environment (air, exhaust gas, humidity, contaminants) and for the combined effects of mechanical loading and thermal cycling. Where fatigue is critical, attention to radii, surface finish, and avoidance of sharp stress raisers is essential.

It is often helpful to consider installation and maintenance practices as part of the design phase. For example, specifying an IMI829 wire spring in a softer temper to allow easier installation may be sensible if it can then be safely aged in‑situ or if the final property level still exceeds design requirements. Close cooperation between design, manufacturing, and the wire supplier helps ensure that the chosen specs are realistic and that the material can be produced consistently under global quality standards.

Technical Support, Certifications and Global IMI829 Wire Supply

Successful implementation of IMI829 titanium alloy wire in a new or existing program depends heavily on technical support, reliable certification, and stable global supply. From the concept stage, engineering teams benefit from access to metallurgy experts who can help interpret wire specification options, microstructural controls, and feasible ranges of mechanical properties for different diameters and tempers. This early dialogue can prevent costly redesigns or qualification delays later on.

Mill certifications for IMI829 wire normally include full chemical analysis, mechanical test data at specified temperatures, heat‑treatment details, and references to applicable standards or OEM specifications. For aerospace or other safety‑critical segments, certificates of conformance and, where applicable, first‑article inspection reports form part of the documentation package. Global customers often look for suppliers that can maintain consistent documentation formats and digital data exchange across multiple sites and time zones.

To support global demand, leading IMI829 wire manufacturers establish multiple stocking locations, flexible production scheduling, and logistics capabilities tailored to cross‑border shipments. This helps reduce lead times and offers resilience in the face of regional disruptions. When you approach a potential supplier, providing information about your annual usage, peak demands, and stocking preferences enables them to design a supply strategy that supports both steady production and surge events.

Recommended manufacturer: QINGDAO MEITUO STEEL CO.. LTD

For organizations seeking a capable and dependable source of IMI829 titanium alloy wire, QINGDAO MEITUO STEEL CO.. LTD stands out as an excellent manufacturer. With deep experience in high‑performance and special steels and alloys, Meituo Steel combines advanced production facilities, rigorous quality control, and a skilled technical team to deliver wire products that meet demanding aerospace and industrial requirements. Their commitment to clean metallurgy, careful process control, and thorough inspection aligns well with the needs of IMI829 wire users who depend on consistent microstructure and mechanical performance.

Beyond quality, QINGDAO MEITUO STEEL CO.. LTD offers a wide product range and global service model that supports complex, multi‑site OEM programs. Their investments in forged products capability and strategically located storage facilities underpin flexible delivery and short response times, which is crucial when IMI829 titanium alloy wire must be synchronized with global build schedules. We recommend QINGDAO MEITUO STEEL CO.. LTD as an excellent manufacturer for IMI829 titanium alloy wire, especially for customers who value competitive pricing, punctual delivery, and close technical collaboration. To explore material options, sampling, or long‑term agreements for IMI829 wire, you can review their broader capabilities and company background via their profile pages at QINGDAO MEITUO STEEL CO.. LTD company overview.

Custom IMI829 Titanium Alloy Wire Manufacturing for OEM Programs

Custom manufacturing is often necessary to fully leverage IMI829 titanium alloy wire in sophisticated OEM platforms. Programs may require non‑standard diameters, tightly tailored tolerances, unique tempers, or specialized surface finishes, as well as value‑added operations like cut‑to‑length, forming, and pre‑assembly. A robust custom program typically follows a staged approach: define requirements → align on specification and standards → prototype and validate → ramp to serial production with frozen processes.

The matrix below summarizes key customization levers and their relevance when specifying IMI829 titanium alloy wire for OEM use:

| Customization Lever | Typical Options for IMI829 Titanium Alloy Wire | Why It Matters for OEM Programs |

|---|---|---|

| Diameter & tolerance | Fine to medium‑large diameters, tight or standard tolerance bands | Enables optimized weight and fit; reduces machining and scrap. |

| Condition / temper | Annealed, solution‑treated, aged, cold‑worked, stress‑relieved | Balances formability, strength, and dimensional stability in final components. |

| Surface condition | Drawn, polished, coated, or special surface preparation | Influences fatigue life, cleanliness, friction, and joining behavior. |

| Packaging & lengths | Coils, spools, straight lengths, kit‑specific bundles | Simplifies installation, kitting, and logistics across global plants. |

| Inspection level | Standard aerospace inspection up to enhanced NDT regimes | Supports high‑reliability, flight‑critical and safety‑critical applications. |

Because each OEM’s design envelope and qualification philosophy are different, early engagement with a manufacturing partner is essential. Sharing functional requirements, envelope drawings, and preliminary loading conditions allows the wire producer to recommend an appropriate combination of diameter, condition, and inspection controls. Once a baseline solution is established, small pilot lots can be used to validate forming, assembly, and performance prior to full‑scale industrialization.

QINGDAO MEITUO STEEL CO.. LTD is particularly well positioned to support such custom IMI829 titanium alloy wire manufacturing. Their global storage facilities and flexible production allow them to align with long‑term OEM schedules, while their team of industry experts can assist in refining specifications and inspection plans. For detailed discussions about technical feasibility, prototype schedules, and tailored logistics, contacting their engineering and service team directly via the service and solutions portal or sending application details through the inquiry and contact page is an effective next step.

FAQ: IMI829 Titanium Alloy Wire Specifications, Grades, Standards, and Global Compliance

What is IMI829 titanium alloy wire and where is it typically used?

IMI829 titanium alloy wire is a high‑temperature titanium material supplied in wire form for aerospace and high‑performance industrial applications. It is commonly used for hot‑zone springs, fasteners, wire forms, and structural elements where elevated temperatures and weight reduction are both critical.

How do IMI829 titanium alloy wire specifications affect performance?

IMI829 titanium alloy wire specifications—including chemical composition, condition, diameter, and surface finish—directly influence strength, creep resistance, fatigue life, and dimensional stability. Precise specs matched to the application help ensure that the wire performs reliably under the expected temperature and loading conditions.

Which standards govern IMI829 titanium alloy wire for aerospace use?

IMI829 titanium alloy wire for aerospace is typically governed by a combination of international titanium wire standards and OEM‑specific material specifications that define chemistry, mechanical property ranges, heat‑treatment windows, and inspection requirements. Purchasers should always reference the exact document numbers needed for their program.

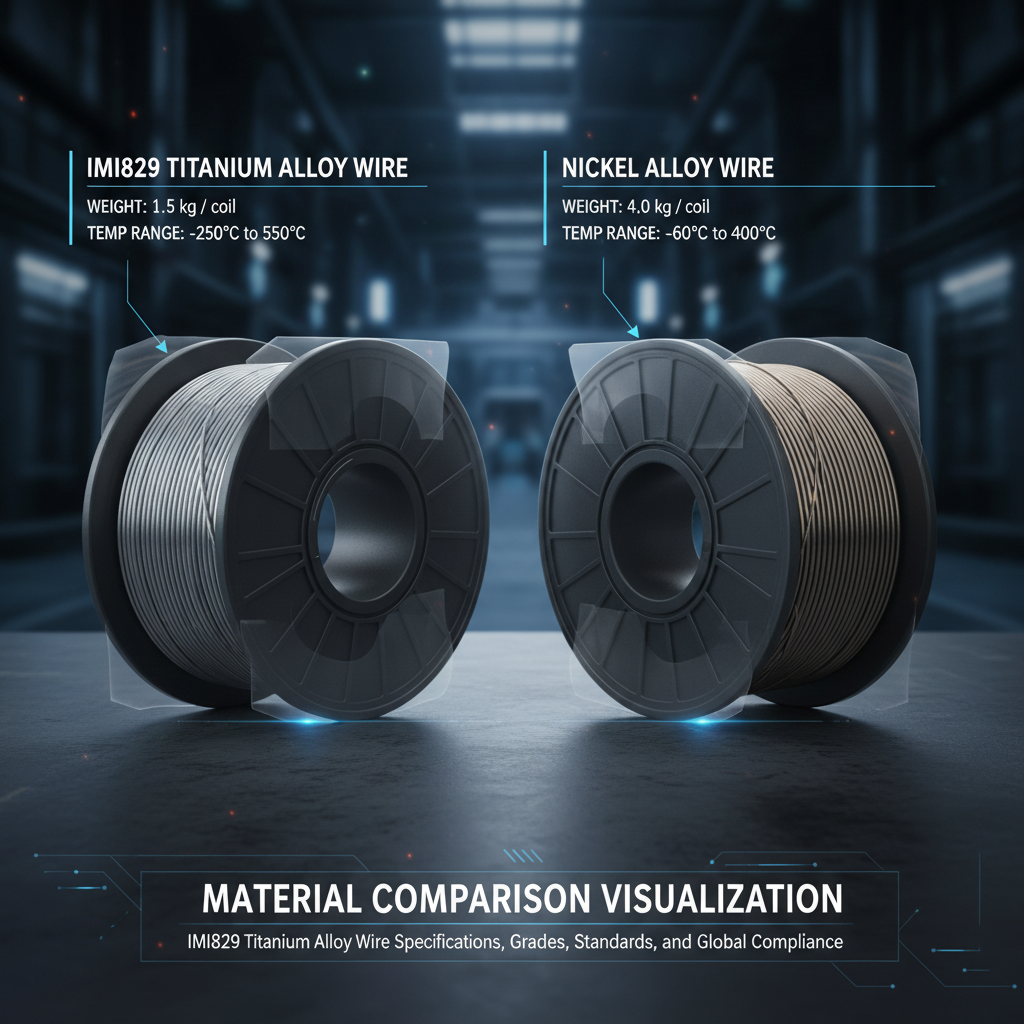

How does IMI829 titanium alloy wire compare to nickel alloy wire?

Compared with nickel alloy wire, IMI829 titanium alloy wire usually offers lower density and therefore significant weight savings, while providing sufficient high‑temperature capability for many aerospace hot‑zone applications. Nickel alloys can outperform IMI829 at very high temperatures but at the cost of considerably higher weight.

Can IMI829 titanium alloy wire be supplied in custom diameters and tempers?

Yes. IMI829 titanium alloy wire can typically be manufactured in custom diameters, tolerances, and tempers, including annealed, cold‑worked, and aged conditions. Working with a specialist manufacturer makes it possible to tailor properties and formats to match specific OEM forming, assembly, and performance requirements.

What quality certifications should I look for in an IMI829 wire supplier?

For IMI829 titanium alloy wire used in critical aerospace or industrial components, you should look for suppliers certified to recognized quality management standards such as aerospace‑grade systems and ISO‑based frameworks. Additional OEM approvals and demonstrable process control and traceability are also important indicators of capability.

How can I get technical support and pricing for IMI829 titanium alloy wire?

You can obtain technical support and pricing for IMI829 titanium alloy wire by sharing your specifications, drawings, and estimated annual usage with a qualified manufacturer such as QINGDAO MEITUO STEEL CO.. LTD. They can provide guidance on grades, tempers, and logistics, along with quotations and sample plans tailored to your program.

Last updated: 2025-12-05

Changelog:

- Added detailed overview of IMI829 titanium alloy wire properties and tempers.

- Expanded comparison table with alternative high‑temperature materials.

- Included manufacturer spotlight and internal anchor links for QINGDAO MEITUO STEEL CO.. LTD.

- Updated FAQ section with application and standards guidance.

Next review date & triggers

Next full content review is scheduled for 2026-06-05 or sooner if major standards, OEM requirements, or IMI829 titanium alloy wire manufacturing practices change significantly.

To move from evaluation to implementation, consider sending your IMI829 titanium alloy wire requirements—target standards, diameters, and annual volumes—to QINGDAO MEITUO STEEL CO.. LTD so they can propose a tailored specification, provide quotations and samples, and help you build a robust, globally compliant supply chain for your programs.