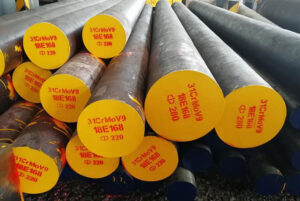

Overview of Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

Waspaloy is a superalloy that’s renowned for its exceptional strength and ability to withstand extreme temperatures. Comprising nickel, chromium, cobalt, molybdenum, and titanium, this high-performance alloy is essential in industries where both high temperature and corrosion resistance are crucial. In this comprehensive guide, we will delve into the intricate details of Waspaloy, exploring its chemical composition, applications, mechanical properties, heat treatment processes, suppliers, and pricing. Whether you’re an engineer, a procurement specialist, or simply curious about advanced materials, this guide is tailored to provide in-depth knowledge in an engaging and easy-to-understand manner.

Chemical Composition of Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

The strength and durability of Waspaloy are primarily due to its unique chemical composition. Let’s break down the elements that make up this superalloy.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 58 – 61 |

| Chromium (Cr) | 18 – 21 |

| Cobalt (Co) | 12 – 15 |

| Molybdenum (Mo) | 3.5 – 5 |

| Titanium (Ti) | 2.75 – 3.25 |

| Aluminum (Al) | 1.2 – 1.6 |

| Boron (B) | 0.003 – 0.01 |

| Zirconium (Zr) | 0.03 – 0.08 |

| Carbon (C) | 0.02 – 0.1 |

| Iron (Fe) | 2.0 max |

| Silicon (Si) | 0.75 max |

| Manganese (Mn) | 0.10 max |

This precise blend of elements gives Waspaloy its remarkable properties, making it indispensable in high-stress, high-temperature environments.

Applications of Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

Waspaloy is used across various industries, particularly where high thermal stability and corrosion resistance are required.

| Industry | Applications |

|---|---|

| Aerospace | Gas turbine engines, jet engine components, rocket engine parts |

| Power Generation | Turbine blades, exhaust systems, combustion chambers |

| Automotive | Turbocharger components, high-performance engine parts |

| Chemical Processing | Heat exchangers, reactors, pressure vessels |

| Oil and Gas | Drilling equipment, high-temperature seals, valves |

Waspaloy’s ability to maintain its mechanical properties at elevated temperatures makes it a go-to material in these demanding applications.

Mechanical Properties of Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

The mechanical properties of Waspaloy are what make it stand out in the world of superalloys.

| Property | Value |

|---|---|

| Density | 8.2 g/cm³ |

| Melting Point | 1320 – 1390°C (2408 – 2534°F) |

| Tensile Strength | 965 MPa (140 ksi) |

| Yield Strength | 725 MPa (105 ksi) |

| Elongation | 18% |

| Hardness (Brinell) | 375 HB |

| Modulus of Elasticity | 200 GPa (29 x 10⁶ psi) |

These properties ensure that Waspaloy components can endure severe stress and high temperatures without compromising performance.

Heat Treatment of Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

Heat treatment is a critical process in enhancing the performance of Waspaloy.

| Heat Treatment Process | Temperature Range (°C) | Duration | Cooling Method |

|---|---|---|---|

| Solution Treatment | 1040 – 1080 | 4 hours | Air cool |

| Aging Treatment (Step 1) | 845 | 24 hours | Air cool |

| Aging Treatment (Step 2) | 760 | 16 hours | Air cool |

Proper heat treatment can significantly improve the mechanical properties, making the alloy even more robust for high-temperature applications.

Suppliers and Pricing Details for Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel

The availability and pricing of Waspaloy can vary depending on the supplier and market conditions.

| Supplier | Location | Price Range ($/kg) | Contact Information |

|---|---|---|---|

| Allegheny Technologies | USA | $100 – $150 | www.atimetals.com |

| Special Metals Corporation | USA | $120 – $160 | www.specialmetals.com |

| VDM Metals | Germany | $110 – $140 | www.vdm-metals.com |

| Haynes International | USA | $115 – $155 | www.haynesintl.com |

| Carpenter Technology | USA | $105 – $145 | www.cartech.com |

It’s important to contact suppliers directly for the most accurate and current pricing information.

Advantages and Disadvantages of Waspaloy Compared to Other Superalloys

Waspaloy has its pros and cons, especially when compared to other superalloys.

| Advantages | Disadvantages |

|---|---|

| High strength at elevated temperatures | Expensive compared to other alloys |

| Excellent oxidation and corrosion resistance | Difficult to machine |

| Good creep resistance | Limited ductility at room temperature |

| Long service life in harsh environments | Requires precise heat treatment |

Understanding these trade-offs is crucial for making informed decisions about material selection in various engineering applications.

FAQ

What is Waspaloy used for?

Waspaloy is primarily used in aerospace and power generation applications due to its high temperature and corrosion resistance.

How does Waspaloy compare to Inconel?

Waspaloy generally offers better high-temperature strength and oxidation resistance compared to Inconel, though it is more challenging to machine and more expensive.

What are the main elements in Waspaloy?

The main elements in Waspaloy are nickel, chromium, cobalt, molybdenum, and titanium.

Can Waspaloy be welded?

Yes, Waspaloy can be welded, but it requires specific techniques and post-weld heat treatment to ensure the integrity of the welds.

Why is Waspaloy so expensive?

Waspaloy’s high cost is due to its complex manufacturing process and the expensive raw materials required to produce it.

Conclusion

Waspaloy Nickel-Chromium-Cobalt-Molybdenum-Titanium Alloy Steel is a marvel of modern engineering materials. Its exceptional properties make it indispensable in high-stress, high-temperature applications. Whether you’re designing jet engines, power generation turbines, or high-performance automotive components, understanding Waspaloy’s characteristics and applications can guide you to make the best material choice for your needs. Its complexity, while challenging, opens doors to innovations that push the boundaries of technology.

For those in the engineering and materials science fields, keeping up-to-date with materials like Waspaloy is crucial. It’s a fascinating alloy that exemplifies the heights of metallurgical advancements, balancing strength, durability, and resistance to extreme environments. Dive into Waspaloy, and you’ll discover the intricate dance of elements that keep our modern world moving and evolving.