Resumen

TIMETAL 679 is a high-performance titanium alloy designed for demanding service where lightweight strength, corrosion resistance, and stable mechanical performance are required. It is a strong option for engineering teams seeking to reduce mass while maintaining durability in aggressive environments and under cyclic loading. Suitable for a wide range of industrial and high-end manufacturing applications, TIMETAL 679 supports reliable performance when conventional materials become weight- or corrosion-limited.

Chemical Composition of TIMETAL 679 (wt%)

- Tin (Sn): 10.50–11.50%

- Zirconium (Zr): 4.00–6.00%

- Aluminum (Al): 2.00–2.50%

- Molibdeno (Mo): 0.80–1.20%

- Silicio (Si): 0.10–0.50%

- Hierro (Fe): ≤ 0.20%

- Oxygen (O): ≤ 0.20%

- Hydrogen (H): ≤ 0.0125%

- Titanium (Ti): Remainder

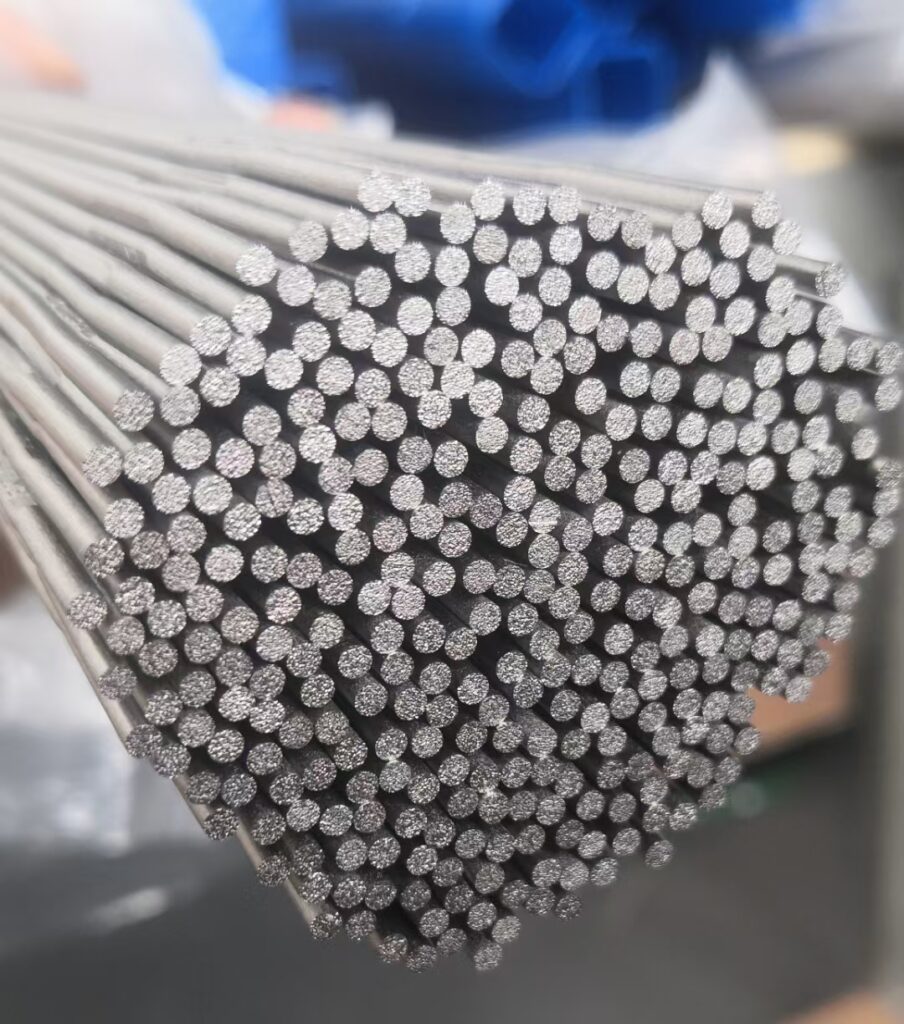

Standard Sizes by Diameter

1) Fine Wire

- Diameter range: 0.1 mm – 1.0 mm

- Common sizes: 0.2 mm, 0.3 mm, 0.5 mm, 0.8 mm, 1.0 mm

2) Medium Wire

- Diameter range: 1.0 mm – 6.0 mm

- Common sizes: 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm, 3.0 mm, 4.0 mm, 5.0 mm, 6.0 mm

Why Choose TIMETAL 679

Engineers select TIMETAL 679 when a component must deliver consistent performance across challenging operating conditions. The alloy is commonly used where strength-to-weight efficiency and long service life are key drivers.

- Lightweight design potential through high strength-to-weight performance

- Corrosion resistance for harsh, wet, or salt-influenced environments

- Dependable performance under cyclic loading for long-life parts

- Suitable for elevated-temperature and thermally variable service conditions

- Supports reduced maintenance and longer replacement intervals in corrosive settings

Typical Application Scenarios

Below are common use cases where TIMETAL 679 can provide a material advantage. Final selection should be validated against the specific design allowables, processing route, and service conditions.

- Aerospace structures and heat-adjacent assemblies where weight reduction is critical

- High-performance automotive and motorsport components requiring stiffness and durability

- Industrial equipment exposed to corrosion, moisture, or chemically aggressive atmospheres

- Energy and power-system components operating under continuous load and elevated temperature

Material Benefits by Application

| Área de aplicación | What It Helps Achieve | Common Design Drivers |

|---|---|---|

| Aeroespacial | Weight reduction with structural reliability | Specific strength, fatigue life, thermal cycling |

| Automotive & Motorsport | Improved performance through mass reduction | Stiffness, durability, harsh duty cycles |

| Industrial / Chemical Exposure | Longer service life in corrosive environments | Corrosion resistance, uptime, maintenance reduction |

| Energy & Power | Stable performance under continuous operation | Elevated temperature capability, reliability |