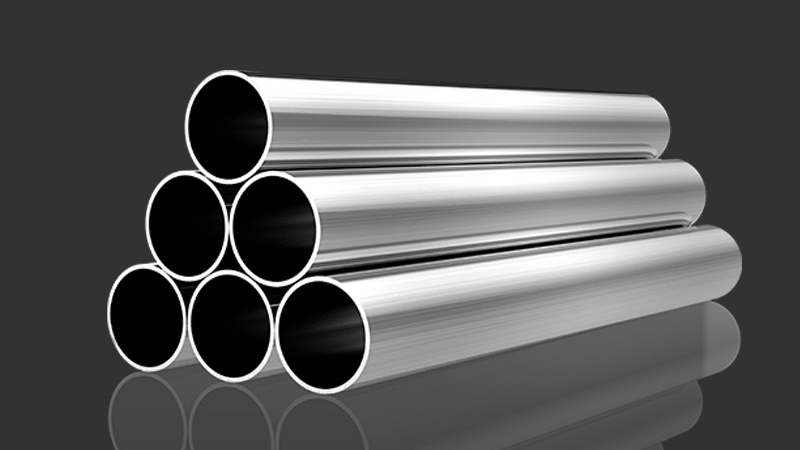

When it comes to materials that combine toughness, resistance, and durability, AISI 420 stainless steel stands out as a prime choice. Known for its excellent corrosion resistance and high polishability, this steel is a staple in various industries. But what makes it so special? Let’s dive into the nitty-gritty details and explore everything you need to know about AISI 420 stainless steel.

Overview of AISI 420 Stainless Steel

AISI 420 stainless steel, often referred to as “surgical steel,” is a high-carbon steel with a minimum chromium content of 12%. This gives it remarkable corrosion resistance properties. Unlike other types of stainless steel, AISI 420 can be hardened through heat treatment, which enhances its mechanical properties.

What’s more? This type of steel is known for its mirror-like finish and high polish, making it aesthetically pleasing for a range of applications from cutlery to medical instruments.

Chemical Composition of AISI 420 Stainless Steel

Understanding the chemical makeup of AISI 420 stainless steel is crucial as it directly influences its properties. Here’s a detailed look at its composition:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15-0.40 |

| Chromium (Cr) | 12.0-14.0 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Nickel (Ni) | 0.75 max |

The Mechanical Properties of AISI 420 Stainless Steel

The mechanical properties of AISI 420 stainless steel make it suitable for various applications. Here’s an in-depth look:

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 515-1035 MPa | 75-150 ksi |

| Yield Strength | 205-860 MPa | 30-125 ksi |

| Modulus of Elasticity | 200 GPa | 29 x 10^6 psi |

| Hardness (Rockwell) | 50-58 HRC | 50-58 HRC |

| Elongation at Break | 5-20% | 5-20% |

Heat Treatment of AISI 420 Stainless Steel

Heat treatment is essential for enhancing the properties of AISI 420 stainless steel. Here’s how the process looks:

| Heat Treatment | Temperature (°C) | Details |

|---|---|---|

| Annealing | 840-900 | Slow cooling in a furnace |

| Hardening | 980-1035 | Oil or air quench |

| Tempering | 150-370 | Based on desired hardness |

Applications of AISI 420 Stainless Steel

AISI 420 stainless steel is versatile and finds use in numerous applications. Let’s explore where you’ll typically find it:

| Application | Details |

|---|---|

| Cutlery | Knives, scissors, and other cutting tools due to its excellent edge retention. |

| Medical Instruments | Surgical tools and dental instruments thanks to its high corrosion resistance. |

| Industrial Machinery | Components that require high wear resistance. |

| Aerospace | Engine parts and components exposed to high stress. |

| Home Appliances | Various household items for its aesthetic finish. |

Suppliers and Pricing Details of AISI 420 Stainless Steel

Finding the right supplier and understanding the pricing are crucial for making an informed decision. Here’s a snapshot:

| Supplier | Location |

|---|---|

| Penn Stainless Products, Inc. | USA |

| Beartech Alloys, Inc. | USA |

| Meituo Steel | China |

| Swagat Steel & Alloys | Indian |

Advantages and Disadvantages of AISI 420 Stainless Steel

When choosing a material, weighing its pros and cons is essential. Here’s a comparative analysis:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Corrosion Resistance | Excellent in mild environments | Not suitable for high chloride environments |

| Hardness | Can be hardened significantly | Requires precise heat treatment |

| Polishing | High polishability | May require frequent maintenance |

| Versatility | Wide range of applications | Higher cost compared to non-stainless steels |

In-Depth Look at AISI 420 Stainless Steel

Chemical Composition and Its Impact

The presence of carbon and chromium in AISI 420 stainless steel is a game-changer. Carbon enhances hardness and strength, while chromium provides the sought-after corrosion resistance. This combination makes it ideal for applications requiring both durability and a high-quality finish.

But there’s more. Manganese and silicon contribute to its overall strength and hardness, although they are present in smaller quantities. Nickel, although not a primary element, can improve toughness and resistance to impact.

Mechanical Properties: A Balancing Act

AISI 420 strikes a balance between tensile strength and ductility. It can endure high stress and strain without deforming, making it a reliable choice for critical applications. The Rockwell hardness rating of 50-58 HRC signifies its ability to retain a sharp edge, crucial for tools like knives and scissors.

Elongation at break indicates how much the material can stretch before breaking. For AISI 420, this ranges between 5-20%, offering a good blend of flexibility and strength.

The Heat Treatment Process

Heat treatment transforms AISI 420 stainless steel from a soft, workable material into a hardened, resilient one. Annealing is the first step, softening the steel to make it easier to work with. Hardening then increases its strength and durability, achieved by heating and then rapidly cooling the steel. Finally, tempering adjusts the hardness to the desired level, ensuring the material isn’t too brittle.

Versatile Applications

From kitchen to industry, AISI 420 stainless steel is everywhere. Its high polish makes it a favorite for cutlery and kitchen utensils. In the medical field, its corrosion resistance ensures that surgical instruments remain sanitary and effective. Industrial machinery benefits from its wear resistance, while the aerospace industry utilizes its high stress tolerance.

Choosing the Right Supplier

When sourcing AISI 420 stainless steel, considering both cost and quality is key. Prices can vary depending on the supplier’s location and the quality of the steel. Suppliers in the USA may offer higher quality at a premium price, while Asian suppliers might provide more cost-effective options.

Advantages vs. Disadvantages

Every material has its strengths and weaknesses. AISI 420 excels in corrosion resistance and hardness but may not be the best choice for environments with high chloride concentrations. Its high polishability is an advantage for aesthetic applications but might require more maintenance to keep it looking pristine.

FAQ

| Question | Answer |

|---|---|

| What is AISI 420 stainless steel used for? | It’s widely used in cutlery, medical instruments, and industrial machinery. |

| How is AISI 420 different from other stainless steels? | It has higher carbon content and can be heat treated to enhance hardness. |

| Is AISI 420 stainless steel magnetic? | Yes, it is magnetic due to its martensitic structure. |

| Can AISI 420 be welded? | Welding is possible but requires preheating and post-weld heat treatment to avoid cracking. |

| How do you polish AISI 420 stainless steel? | Polishing involves multiple steps including grinding, buffing, and using polishing compounds for a mirror finish. |

Conclusion

AISI 420 stainless steel is a versatile and robust material that excels in numerous applications due to its excellent corrosion resistance, hardness, and aesthetic appeal. Whether you’re looking for a reliable material for cutlery, medical instruments, or industrial machinery, AISI 420 is a worthy contender.

By understanding its chemical composition, mechanical properties, heat treatment process, and applications, you can make an informed decision on whether this stainless steel meets your specific needs. Remember to consider the advantages and disadvantages, and choose a supplier that offers the best balance of cost and quality.

If you’re still on the fence, think about this: What’s more important to you—cost, durability, or aesthetic appeal? Weigh your options carefully, and AISI 420 might just be the perfect fit for your project.

Feel free to reach out with any more questions about AISI 420 stainless steel, and don’t hesitate to consult with experts to get the most out of this remarkable material. Happy steel hunting!