If you’re diving into the world of materials science, particularly steel alloys, you might have come across 40CrNiMoA steel. This alloy is renowned for its exceptional strength, toughness, and versatility, making it a favorite in various demanding applications. But what makes 40CrNiMoA stand out? Let’s delve deep into its characteristics, uses, and more.

Overview of 40CrNiMoA Steel

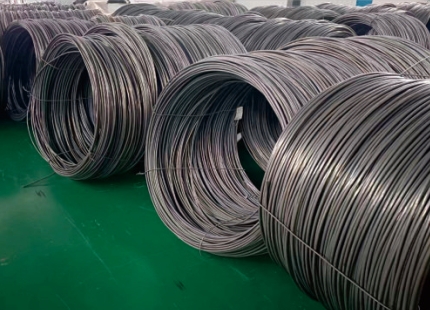

40CrNiMoA is a low-alloy steel with high hardenability and strength. Its chemical composition includes chromium, nickel, and molybdenum, which enhance its mechanical properties. This steel is often utilized in manufacturing heavy-duty components that require high strength and toughness, such as shafts, gears, and fasteners.

Chemical Composition and Properties

Understanding the chemical composition of 40CrNiMoA steel is crucial as it directly impacts its properties and performance. Here’s a detailed look at its composition:

| Element | Percentage |

|---|---|

| Carbon (C) | 0.37-0.44% |

| Silicon (Si) | 0.17-0.37% |

| Manganese (Mn) | 0.50-0.80% |

| Chromium (Cr) | 0.90-1.20% |

| Nickel (Ni) | 0.50-0.80% |

| Molybdenum (Mo) | 0.15-0.25% |

This specific composition gives 40CrNiMoA steel its desirable properties:

- High strength and toughness: Ideal for heavy-duty applications.

- Good hardenability: Ensures deep hardening during heat treatment.

- Resistance to wear and tear: Suitable for parts subjected to high stress and friction.

- Excellent fatigue resistance: Perfect for components that endure repetitive stress cycles.

Mechanical Properties

Mechanical properties of 40CrNiMoA steel are essential for determining its suitability for various applications. Here are the key mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 900-1100 MPa |

| Yield Strength | 700 MPa |

| Elongation | 12% |

| Reduction of Area | 50% |

| Hardness (HRC) | 28-34 |

Applications of 40CrNiMoA Steel

40CrNiMoA steel’s robust properties make it a go-to material in several industries. Here’s a detailed table showcasing its common applications:

| Application | Description |

|---|---|

| Shafts | Used in machinery for transferring motion or torque. |

| Gears | Integral in automotive and industrial machinery for power transmission. |

| Fasteners | High-strength bolts and nuts for heavy-duty applications. |

| Crankshafts | Essential in engines, transforming linear piston motion into rotational motion. |

| Connecting Rods | Connects piston to crankshaft in engines, withstanding high stress and fatigue. |

| Tooling Components | High-performance tools for manufacturing and machining. |

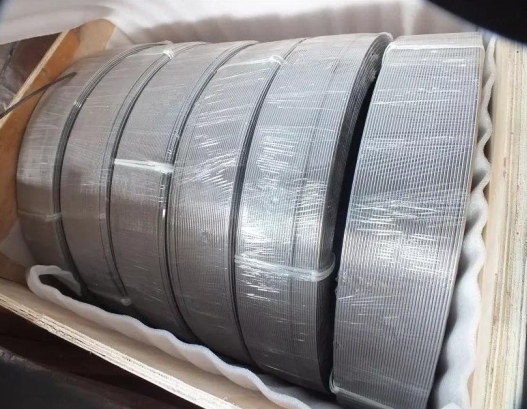

Specifications, Sizes, and Standards

When dealing with 40CrNiMoA steel, knowing the available specifications, sizes, and standards is crucial. Here’s a comprehensive table:

| Specification | Details |

|---|---|

| Standard | GB/T 3077-1999 |

| Sizes | Available in various sizes ranging from 10mm to 500mm in diameter. |

| Grades | Different grades based on the specific mechanical requirements. |

Suppliers and Pricing Details

Selecting the right supplier is essential for ensuring the quality and reliability of 40CrNiMoA steel. Here’s a list of some reputed suppliers and pricing details:

| Supplier | Location | Price (per ton) |

|---|---|---|

| Baosteel Group | China | $1200 – $1500 |

| ArcelorMittal | Global | $1300 – $1600 |

| Nippon Steel | Japan | $1400 – $1700 |

| Tata Steel | India | $1250 – $1550 |

Advantages of 40CrNiMoA Steel

Why choose 40CrNiMoA steel? Here are some compelling reasons:

- Exceptional Strength: Ideal for high-stress applications.

- Versatility: Suitable for a wide range of components and industries.

- Durability: Long-lasting performance even under harsh conditions.

- Fatigue Resistance: Excellent for components subjected to cyclic loading.

Disadvantages of 40CrNiMoA Steel

However, no material is without its drawbacks. Consider these limitations:

- Cost: Higher price compared to some other steels.

- Machinability: Requires careful machining due to its hardness.

- Availability: May not be as readily available as more common steel types.

Comparison with Other Steels

How does 40CrNiMoA stack up against other steels? Let’s compare:

| Property | 40CrNiMoA | 40Cr | 42CrMo |

|---|---|---|---|

| Strength | High | Medium | Very High |

| Toughness | High | Medium | Very High |

| Cost | High | Medium | Very High |

| Applications | Heavy-duty components | General purpose | High-stress components |

Powder Models of 40CrNiMoA Steel

When it comes to specific metal powder models, 40CrNiMoA has several variants tailored for different uses. Here’s a look at some notable models:

- PMS 40CrNiMoA-100

- Fine particle size for precision applications.

- Used in additive manufacturing and 3D printing.

- PMS 40CrNiMoA-150

- Medium particle size.

- Suitable for powder metallurgy applications.

- PMS 40CrNiMoA-200

- Coarse particle size.

- Ideal for large-scale component manufacturing.

- PMS 40CrNiMoA-HS

- High-strength powder.

- Used in aerospace and automotive industries.

- PMS 40CrNiMoA-HT

- High-temperature resistant.

- Suitable for applications involving extreme heat.

- PMS 40CrNiMoA-W

- Wear-resistant powder.

- Perfect for tooling and machining components.

- PMS 40CrNiMoA-F

- Fatigue-resistant.

- Used in cyclic load-bearing applications.

- PMS 40CrNiMoA-C

- Corrosion-resistant.

- Suitable for harsh environmental conditions.

- PMS 40CrNiMoA-M

- Malleable powder.

- Used in custom component fabrication.

- PMS 40CrNiMoA-E

- Economical version.

- Budget-friendly option for less demanding applications.

FAQ

What is 40CrNiMoA steel?

40CrNiMoA is a low-alloy steel known for its high strength, toughness, and good hardenability. It’s commonly used in manufacturing heavy-duty components.

What are the key properties of 40CrNiMoA steel?

Key properties include high tensile strength (900-1100 MPa), good toughness, excellent fatigue resistance, and wear resistance.

Where is 40CrNiMoA steel used?

It’s used in making shafts, gears, fasteners, crankshafts, connecting rods, and tooling components, among others.

How does 40CrNiMoA steel compare to other steels?

Compared to steels like 40Cr and 42CrMo, 40CrNiMoA offers a balance of high strength and toughness, but at a higher cost.

What are the common specifications for 40CrNiMoA steel?

It follows the GB/T 3077-1999 standard, with sizes ranging from 10mm to 500mm in diameter, and various grades based on mechanical requirements.

Who are the top suppliers of 40CrNiMoA steel?

Some top suppliers include Baosteel Group, ArcelorMittal, Nippon Steel, and Tata Steel.

What are the advantages of using 40CrNiMoA steel?

Its main advantages are its exceptional strength, versatility, durability, and excellent fatigue resistance.

What are the disadvantages of 40CrNiMoA steel?

Disadvantages include higher cost, challenging machinability, and limited availability compared to more common steels.

What are some specific metal powder models of 40CrNiMoA steel?

Notable models include PMS 40CrNiMoA-100, PMS 40CrNiMoA-150, PMS 40CrNiMoA-200, PMS 40CrNiMoA-HS, and others, each tailored for different applications.

Is 40CrNiMoA steel suitable for high-temperature applications?

Yes, models like PMS 40CrNiMoA-HT are specifically designed for high-temperature resistance.