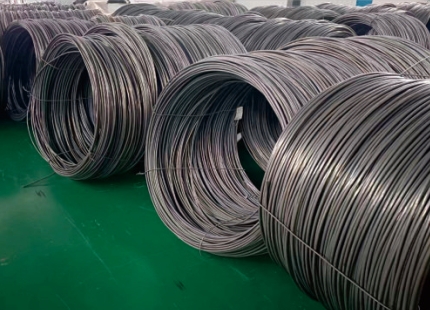

Imagine a metal wire that’s incredibly strong, yet remarkably lightweight. A material that shrugs off heat like a champ and can withstand repeated stress without breaking a sweat. That’s the magic of Dây titan IMI834, a near-alpha titanium alloy that’s become a superstar in the world of aerospace, medical, and high-performance applications.

This article will be your one-stop shop for everything IMI834. We’ll delve into its composition, properties, applications, and even explore some of the top suppliers. Buckle up, because we’re about to embark on a journey into the fascinating world of this exceptional metal wire.

Composition and Properties of IMI834

IMI834 belongs to a special group of titanium alloys called near-alpha alloys. Unlike pure titanium, which is fantastic for corrosion resistance but a bit soft, near-alpha alloys strike a perfect balance. They incorporate a small amount of other elements, typically aluminum and oxygen, to boost their strength without sacrificing too much of titanium’s inherent lightness.

Here’s a closer look at IMI834’s composition:

| Nguyên tố | Weight % |

|---|---|

| Titanium (Ti) | Cân bằng |

| Aluminum (Al) | 5.5 – 6.8 |

| Oxygen (O) | 0.15 – 0.25 |

| Sắt (Fe) | Max 0.30 |

| Nitrogen (N) | Max 0.05 |

This specific blend of elements grants IMI834 a unique set of properties that make it perfect for demanding applications. Let’s explore some of its key characteristics:

- Mid-Range Strength: Compared to pure titanium, IMI834 boasts significantly higher strength. This makes it ideal for situations where the material needs to handle significant loads without succumbing to deformation. Think aircraft landing gear or medical implants.

- Excellent Elevated Temperature Properties: IMI834 doesn’t flinch when the heat is on. It retains its strength and stability even at elevated temperatures, making it a valuable asset in high-performance engines and aerospace components.

- Good Fatigue Resistance: Imagine a material that can withstand constant stress and strain without breaking. That’s precisely what IMI834 brings to the table. Its impressive fatigue resistance makes it perfect for applications that experience repeated cycles of stress, such as springs and vibration dampeners.

- Good Weldability: IMI834 plays nicely with others. It can be readily welded using various techniques, which is crucial for creating complex structures from this exceptional wire.

Metal Powders for Additive Manufacturing

While IMI834 is primarily used as wire, advancements in additive manufacturing have opened doors for its use in 3D printing. Here are some specific metal powder models compatible with IMI834 for additive manufacturing:

- AMCP CP Ti-6Al-5.5V ELI (Electron Beam-Melted): This powder offers excellent mechanical properties and is ideal for high-performance applications.

- APOS Ti-6Al-4V (Gas-Atomized): This cost-effective option delivers good mechanical properties and is suitable for a wide range of applications.

- Höganäs AM Titanium (Gas-Atomized): Renowned for its high purity and consistent quality, this powder produces parts with exceptional mechanical properties.

- LPW Ti64 (AM) (Gas-Atomized): This powder is known for its excellent flowability and printability, making it ideal for complex geometries.

- SLM Solutions Ti64 (Gas-Atomized): Optimized for laser beam melting processes, this powder delivers high-density parts with superior mechanical properties.

- ARCAM Ti6Al4V (Electron Beam-Melted): This premium option offers exceptional performance and is ideal for demanding applications in the aerospace and medical industries.

- Special Metals Corporation (SMC) Ti-6Al-4V (Gas-Atomized): A versatile powder suitable for a wide range of additive manufacturing processes.

- Proto Labs – 316L Stainless Steel (Gas-Atomized): While not an exact match for IMI834, this powder offers a good alternative for applications where high strength and corrosion resistance are priorities.

Remember: Consultant with your chosen metal powder supplier to ensure compatibility with your specific 3D printing equipment and desired application.

Ứng dụng của Dây titan IMI834

The unique blend of properties possessed by IMI834 makes it a highly sought-after material across various industries. Here are some of the most common applications of IMI834 wire:

Aerospace:

The relentless pursuit of lightweight yet robust materials makes IMI834 a star player in the aerospace industry. Its ability to handle high stress, resist heat, and maintain structural integrity positions it perfectly for various applications:

- Landing Gear Components: Imagine the immense pressure exerted on landing gear as a plane touches down. IMI834’s strength ensures these critical components can withstand the impact without compromising safety.

- Engine Components: High-performance engines generate significant heat. IMI834’s exceptional elevated temperature properties make it suitable for parts like compressor blades and discs that operate in scorching environments.

- Airframe Components: From lightweight airframes to robust structural elements, IMI834’s versatility allows for its use in various airframe components where strength and weight reduction are crucial.

Medical:

Biocompatibility is the name of the game when it comes to medical implants. IMI834 excels in this area, offering a perfect blend of:

- Strength: Medical implants like bone screws and plates need to be strong enough to support bone healing and withstand daily wear and tear. IMI834 delivers the necessary strength for these critical applications.

- Corrosion Resistance: The human body is a complex environment. IMI834’s excellent corrosion resistance minimizes the risk of implant rejection and ensures long-term functionality.

- Biocompatibility: Our bodies are incredibly sensitive to foreign materials. IMI834’s biocompatible nature makes it a safe and reliable choice for implants that can coexist peacefully with human tissue.

Other Applications:

The impressive properties of IMI834 extend beyond aerospace and medicine. Here are some additional applications where it shines:

- High-Performance Automotive Parts: From lightweight yet strong suspension components to high-performance engine parts, IMI834 helps push the boundaries of automotive design.

- Chemical Processing Equipment: IMI834’s corrosion resistance makes it suitable for handling harsh chemicals used in various industrial processes.

- Sporting Goods: From high-end golf clubs to lightweight yet durable prosthetics, IMI834 finds its way into a surprising variety of sporting goods where strength and weight reduction are desired.

Specifications and Standards of Dây titan IMI834

When working with IMI834, it’s crucial to understand the various specifications and standards that ensure consistent quality and performance. Here’s a breakdown of some key considerations:

| Tài sản | Description |

|---|---|

| Standards: | IMI834 typically adheres to international aerospace standards like AMS 4928 and ASTM B265. These standards define the chemical composition, mechanical properties, and processing requirements for the material. |

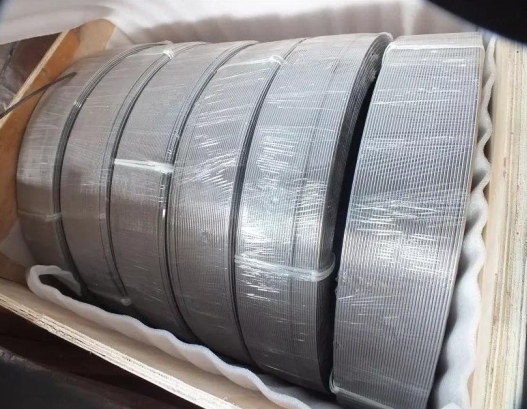

| Forms: | IMI834 is available in various forms like wire, bar, sheet, and plate. The specific form chosen depends on the intended application and desired final product geometry. |

| Sizes: | The available wire diameters for IMI834 typically range from 0.05 mm to 12.7 mm (0.002 inches to 0.5 inches). |

| Heat Treatment: | The final properties of IMI834 can be further tailored through various heat treatment processes like solution annealing and aging. |

Nhà cung cấp và Giá cả

Finding reliable suppliers for IMI834 is essential for ensuring the quality and performance of your project. Here’s a glimpse into the world of IMI834 suppliers and pricing:

| Nhà cung cấp | Description | Pricing (estimate) |

|---|---|---|

| Alcoa | A global leader in aluminum and titanium products, Alcoa offers IMI834 in various forms and specifications. | Pricing varies depending on quantity, form, and size. Expect a premium compared to standard titanium. |

| ATI Specialty Materials | A leading manufacturer of specialty metals, ATI provides IMI834 in various forms and can offer custom solutions. | Pricing is similar to Alcoa; expect a premium for high-performance materials. |

| Special Metals Corporation | Another major player in the specialty metals market, Special Metals offers IMI834 wire, bar, and sheet products. | Pricing may vary slightly compared to Alcoa and ATI. |

Remember: It’s crucial to contact suppliers directly for the most up-to-date pricing and availability information.

Pros and Cons of IMI834

While IMI834 boasts a remarkable set of properties, it’s essential to consider both its advantages and limitations before making a decision.

Pros:

- High Strength: Compared to pure titanium, IMI834 offers significantly higher strength, making it ideal for load-bearing applications.

- Excellent Elevated Temperature Properties: IMI834 retains its strength and stability even at high temperatures, perfect for aerospace and high-performance engine components.

- Good Fatigue Resistance: This material can withstand repeated stress and strain without breaking, making it suitable for springs and vibration dampeners.

- Good Weldability: IMI834 can be readily welded using various techniques, which is crucial for creating complex structures.

- Biocompatible: In the medical field, IMI834’s biocompatibility makes it a safe and reliable choice for long-lasting implants.

- Lightweight: Despite its strength, IMI834 remains lightweight, contributing to weight reduction in applications like aerospace and high-performance automotive parts.

Cons:

- Cost: Compared to standard titanium or other common engineering materials, IMI834 carries a higher price tag due to its unique properties and processing requirements.

- Machinability: While machinable, IMI834 can be more challenging to machine compared to some other metals. This can translate to higher machining costs and require specialized tooling.

- Limited Availability: IMI834 isn’t as readily available as some other materials. Lead times for obtaining it may be longer, especially for specific forms and sizes.

Making an Informed Decision:

Ultimately, the decision to use IMI834 depends on your specific project requirements and priorities. If your application demands exceptional strength, high-temperature performance, and biocompatibility, and you can accommodate the cost and potential machining challenges, then IMI834 is a fantastic choice. However, if budget is a major concern and readily available materials suffice for your needs, then exploring alternative options might be more suitable.

Câu hỏi thường gặp

Here are some of the most common questions regarding Titanium Wire IMI834, answered in a clear and concise format:

| Câu hỏi | Trả lời |

|---|---|

| What is IMI834? | IMI834 is a near-alpha titanium alloy known for its high strength, excellent elevated temperature properties, good fatigue resistance, and biocompatibility. |

| What are some applications of IMI834? | IMI834 finds use in various industries, including aerospace (landing gear components, engine components, airframe components), medical (bone screws, plates, implants), high-performance automotive parts, chemical processing equipment, and sporting goods. |

| What are the advantages of IMI834? | The key advantages of IMI834 include high strength, excellent high-temperature performance, good fatigue resistance, good weldability, biocompatibility, and lightweight properties. |

| What are the disadvantages of IMI834? | Some drawbacks of IMI834 are its higher cost compared to standard titanium, increased machining challenges, and potentially limited availability depending on the form and size required. |

| What are some alternatives to IMI834? | Depending on your specific application requirements, alternative materials like Ti-6Al-4V (another titanium alloy), high-strength steels, or even advanced composites might be considered. |

| Where can I buy IMI834? | Several reputable suppliers offer IMI834, including Alcoa, ATI Specialty Materials, and Special Metals Corporation. It’s recommended to contact them directly for current pricing and availability information. |

Kết luận

IMI834 stands as a testament to the power of material science. By combining strength, heat resistance, biocompatibility, and lightweight properties, it has carved a niche for itself in demanding applications across various industries. Whether it’s keeping airplanes aloft, ensuring the success of medical implants, or pushing the boundaries of high-performance design, IMI834 continues to be a material of choice for engineers and designers seeking the best possible performance.