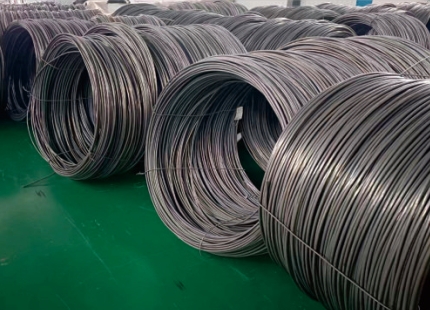

Overview of Titanium Wire TC4

Titanium Wire TC4, also known as Ti-6Al-4V, is a versatile and highly sought-after alloy in various industries. Its unique properties, such as high strength, lightweight, excellent corrosion resistance, and biocompatibility, make it an ideal choice for applications ranging from aerospace to medical devices. This guide dives deep into the specifics of Titanium Wire TC4, exploring its types, compositions, properties, applications, specifications, suppliers, and more.

Types and Compositions of Titanium Wire TC4

Titanium Wire TC4 is available in several models, each designed for specific applications. Here are some of the key models:

| Model | Composition | Description |

|---|---|---|

| TC4-1 | Ti-6Al-4V | Standard alloy with balanced properties for general use. |

| TC4-2 | Ti-6Al-4V ELI | Extra-low interstitial version for improved ductility and toughness. |

| TC4-3 | Ti-6Al-4V STA | Solution-treated and aged for enhanced strength. |

| TC4-4 | Ti-6Al-4V SP | Special processing for superior surface finish. |

| TC4-5 | Ti-6Al-4V PM | Powder metallurgy variant for consistent microstructure. |

| TC4-6 | Ti-6Al-4V G5 | Grade 5 variant, optimized for 3D printing and additive manufacturing. |

| TC4-7 | Ti-6Al-4V AMS 4911 | Compliant with AMS 4911 standards for aerospace applications. |

| TC4-8 | Ti-6Al-4V Grade 23 | Medical-grade alloy with superior biocompatibility. |

| TC4-9 | Ti-6Al-4V HN | High-nitrogen variant for enhanced strength and hardness. |

| TC4-10 | Ti-6Al-4V WF | Wire-form specifically designed for welding applications. |

Properties and Characteristics of Titanium Wire TC4

Titanium Wire TC4 boasts a range of impressive properties that make it suitable for a variety of demanding applications. Let’s explore these properties in detail:

| Property | Description |

|---|---|

| Density | 4.43 g/cm³ – Lightweight compared to other metals like steel and nickel alloys. |

| Tensile Strength | 895 MPa – High strength, making it suitable for structural applications. |

| Yield Strength | 825 MPa – Maintains integrity under stress without permanent deformation. |

| Modulus of Elasticity | 110 GPa – Provides flexibility while maintaining strength. |

| Melting Point | 1604-1660°C – Suitable for high-temperature applications. |

| Thermal Conductivity | 6.7 W/m·K – Moderate thermal conductivity for heat dissipation. |

| Corrosion Resistance | Excellent – Resists corrosion in marine, chemical, and medical environments. |

| Biocompatibility | Superior – Safe for use in medical implants and devices. |

| Machinability | Moderate – Requires specialized tools for precision machining. |

| Fatigue Resistance | High – Suitable for cyclic loading applications. |

Applications of Titanium Wire TC4

Titanium Wire TC4 finds use across a variety of industries due to its unique properties. Here are some notable applications:

| Industry | Application |

|---|---|

| Aerospace | Airframe components, engine parts, fasteners, and landing gear. |

| Medical | Surgical implants, dental implants, and medical devices. |

| Automotive | High-performance parts, exhaust systems, and springs. |

| Marine | Offshore oil and gas equipment, underwater connectors, and submersible components. |

| Chemical | Heat exchangers, chemical processing equipment, and reactor vessels. |

| Sporting Goods | Golf club heads, bicycle frames, and tennis rackets. |

| Jewelry | Hypoallergenic jewelry and body piercings. |

| Additive Manufacturing | 3D printing of complex parts and prototypes. |

| Architecture | Structural components and decorative elements in buildings and infrastructure. |

| Energy | Components for power generation and storage systems. |

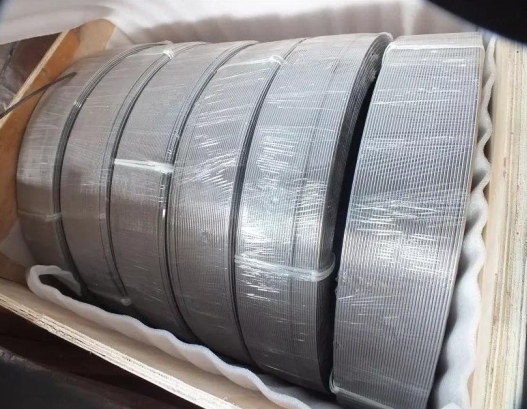

Specifications, Sizes, Grades, and Standards

When selecting Titanium Wire TC4 for specific applications, understanding the available specifications, sizes, grades, and standards is crucial. Here’s a detailed look:

| Specification | Size Range | Grade | Standard |

|---|---|---|---|

| Diameter | 0.1mm to 5.0mm | Grade 5 | ASTM B348 |

| Length | Custom lengths | Grade 23 | AMS 4911 |

| Tolerance | +/- 0.01mm | ELI (Extra Low Interstitial) | ISO 5832-3 |

| Surface Finish | Polished, Pickled | Grade 9 | MIL-T-9046 |

| Coatings | Uncoated, Coated | Grade 12 | ASTM F136 |

| Heat Treatment | Annealed, Aged | Standard | AMS 4928 |

| Form | Wire, Rod, Bar | High Nitrogen | ASTM B863 |

Suppliers and Pricing Details

Finding the right supplier for Titanium Wire TC4 can be a critical factor in ensuring quality and cost-effectiveness. Here’s an overview of some top suppliers and their pricing:

| Supplier | Region | Pricing (per kg) | Contact Information |

|---|---|---|---|

| Titanium Industries | USA | $200 – $250 | www.titanium.com |

| Baoji Titanium | China | $150 – $200 | www.baoji-titanium.com |

| ATI Metals | USA | $220 – $270 | www.atimetals.com |

| VSMPO-AVISMA | Russia | $180 – $230 | www.vsmpo.ru |

| Western Titanium | USA | $210 – $260 | www.westerntitanium.com |

| Daido Steel | Japan | $190 – $240 | www.daido.co.jp |

| Hangzhou King Titanium | China | $160 – $210 | www.king-titanium.com |

| Timet | USA | $230 – $280 | www.timet.com |

| Tronox | Australia | $170 – $220 | www.tronox.com |

| Titanium Metal Supply | USA | $200 – $250 | www.titaniummetalsupply.com |

Pros and Cons of Titanium Wire TC4

While Titanium Wire TC4 offers numerous advantages, it also comes with some limitations. Here’s a comparative look at its pros and cons:

| Aspect | Pros | Cons |

|---|---|---|

| Strength-to-Weight Ratio | High strength while remaining lightweight. | Higher cost compared to some alternatives. |

| Corrosion Resistance | Excellent in harsh environments. | Requires specialized handling to prevent contamination. |

| Biocompatibility | Safe for medical and dental applications. | Potential for allergic reactions in rare cases. |

| Machinability | Achievable with the right tools and techniques. | More challenging to machine than some metals. |

| Thermal Properties | Suitable for high-temperature applications. | Moderate thermal conductivity compared to copper or aluminum. |

| Durability | Long-lasting with high fatigue resistance. | Susceptible to hydrogen embrittlement in certain conditions. |

| Applications | Versatile for a wide range of industries. | Limited availability in some regions. |

Detailed Analysis of Key Models

TC4-1: The Standard Alloy

TC4-1 is the most commonly used variant of Titanium Wire TC4. Its balanced properties make it suitable for a wide range of applications, from aerospace components to medical implants. The standard composition of Ti-6Al-4V offers high strength and good corrosion resistance, making it a versatile choice for many industries.

TC4-2: Extra-Low Interstitial (ELI)

The TC4-2 variant, also known as Ti-6Al-4V ELI, features extra-low interstitial elements. This modification enhances the alloy’s ductility and toughness, making it ideal for critical applications such as medical implants and deep-sea components. The reduced interstitial elements also improve the alloy’s performance at cryogenic temperatures.

TC4-3: Solution-Treated and Aged (STA)

TC4-3 undergoes solution treatment and aging, which significantly enhances its strength and hardness. This makes it suitable for high-stress applications where maximum material performance is required. Common uses include aerospace fasteners and high-performance automotive parts.

TC4-4: Special Processing (SP)

The TC4-4 variant is produced with special processing techniques that result in a superior surface finish. This makes it an excellent choice for applications where surface integrity is critical, such as in precision instruments and high-end jewelry.

TC4-5: Powder Metallurgy (PM)

TC4-5 is manufactured using powder metallurgy, which ensures a consistent microstructure and excellent mechanical properties. This variant is particularly useful for additive manufacturing and 3D printing, where uniformity and precision are paramount.

TC4-6: Grade 5 for 3D Printing

TC4-6, also known as Ti-6Al-4V Grade 5, is optimized for 3D printing and additive manufacturing processes. Its fine grain structure and excellent mechanical properties make it a preferred choice for producing complex geometries and lightweight structures.

TC4-7: AMS 4911 Compliant

TC4-7 complies with AMS 4911 standards, ensuring it meets stringent requirements for aerospace applications. This variant is used extensively in aircraft components, including airframes, engine parts, and fasteners, where reliability and performance are crucial.

TC4-8: Medical-Grade (Grade 23)

TC4-8, also known as Ti-6Al-4V Grade 23, is a medical-grade alloy with superior biocompatibility. It is commonly used in surgical implants, dental implants, and other medical devices due to its excellent tissue compatibility and mechanical properties.

TC4-9: High-Nitrogen (HN)

The TC4-9 variant includes a higher nitrogen content, which enhances its strength and hardness. This makes it suitable for demanding applications such as cutting tools, high-stress fasteners, and other components that require exceptional wear resistance.

TC4-10: Wire-Form for Welding (WF)

TC4-10 is specifically designed in wire form for welding applications. Its composition and processing ensure optimal weldability and consistent performance in joining operations. This variant is widely used in aerospace and automotive industries for welding critical components.

Advantages of Titanium Wire TC4 Manufacturer

Choosing a reliable manufacturer for Titanium Wire TC4 is crucial for ensuring product quality and performance. Here are some advantages of working with reputable manufacturers:

- Quality Assurance: Reputable manufacturers adhere to strict quality control standards, ensuring consistent product quality and performance.

- Technical Expertise: Experienced manufacturers offer technical support and guidance, helping you select the right variant for your application.

- Customization: Leading manufacturers provide customization options to meet specific project requirements, such as custom sizes, finishes, and coatings.

- Reliable Supply Chain: Established manufacturers have robust supply chains, ensuring timely delivery and availability of materials.

- Compliance: Reputable manufacturers comply with international standards and certifications, providing assurance of product reliability and safety.

Disadvantages of Titanium Wire TC4 Manufacturer

While there are many advantages, there are also some potential disadvantages to consider when choosing a Titanium Wire TC4 manufacturer:

- Higher Costs: High-quality products from reputable manufacturers often come at a premium price.

- Lead Times: Custom orders or high-demand products may have longer lead times, impacting project timelines.

- Limited Availability: Certain specialized variants may have limited availability, requiring advance planning and ordering.

- Regional Restrictions: Some manufacturers may have regional restrictions, limiting their ability to supply globally.

Comparative Analysis: Titanium Wire TC4 vs. Other Alloys

When selecting materials for specific applications, it’s essential to compare Titanium Wire TC4 with other alloys. Here’s a detailed comparison:

| Property | Titanium Wire TC4 | Stainless Steel | Aluminum Alloys | Nickel Alloys |

|---|---|---|---|---|

| Strength-to-Weight Ratio | High | Moderate | Low | High |

| Corrosion Resistance | Excellent | Good | Fair | Excellent |

| Biocompatibility | Superior | Moderate | Poor | Excellent |

| Thermal Conductivity | Moderate | High | High | Low |

| Machinability | Moderate | High | High | Low |

| Cost | High | Low | Low | High |

| Fatigue Resistance | High | Moderate | Low | High |

| Density | Low | High | Very Low | High |

FAQ

Q1: What is Titanium Wire TC4 used for?

Titanium Wire TC4 is used in aerospace, medical, automotive, marine, chemical, and other industries due to its high strength, corrosion resistance, and biocompatibility.

Q2: What are the key properties of Titanium Wire TC4?

Key properties include high tensile strength, excellent corrosion resistance, biocompatibility, and moderate thermal conductivity.

Q3: How is Titanium Wire TC4 different from other titanium alloys?

Titanium Wire TC4 (Ti-6Al-4V) is distinguished by its balance of properties, making it suitable for a wide range of applications. Other alloys may have different compositions tailored for specific uses.

Q4: What are the available sizes and forms of Titanium Wire TC4?

Titanium Wire TC4 is available in various diameters, lengths, and forms, including wire, rod, and bar. Custom sizes and finishes are also available.

Q5: Why is Titanium Wire TC4 preferred in medical applications?

Its superior biocompatibility, corrosion resistance, and strength make it ideal for medical implants and devices.

Q6: How does the cost of Titanium Wire TC4 compare to other materials?

Titanium Wire TC4 is more expensive than many other materials like stainless steel and aluminum but offers superior performance in demanding applications.

Q7: Can Titanium Wire TC4 be used in welding applications?

Yes, TC4-10 variant is specifically designed for welding applications, providing optimal weldability.

Q8: What standards does Titanium Wire TC4 comply with?

It complies with various standards such as ASTM B348, AMS 4911, MIL-T-9046, and ISO 5832-3, depending on the specific variant.

Q9: How does Titanium Wire TC4 perform in high-temperature environments?

It performs well due to its high melting point and stability at elevated temperatures, making it suitable for aerospace and industrial applications.

Q10: Are there any environmental concerns with using Titanium Wire TC4?

Titanium is non-toxic and biocompatible, posing minimal environmental concerns. However, processing and extraction can have environmental impacts.

Conclusion

Titanium Wire TC4 is a remarkable material with a wide range of applications due to its exceptional properties. Whether you’re in aerospace, medical, automotive, or another industry, understanding the different models, their compositions, and their specific uses can help you make an informed decision. By choosing the right supplier and understanding the pros and cons, you can leverage the full potential of Titanium Wire TC4 for your projects.