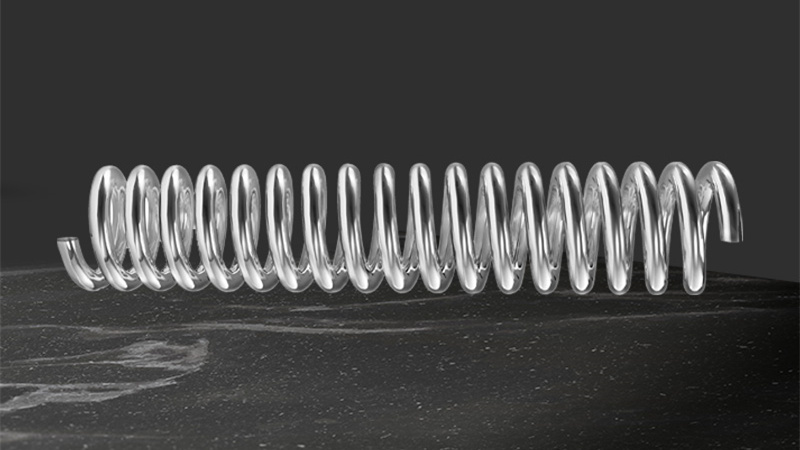

La puissance de l'acier spécial 60SiCr7 Acier à ressort

Dans le domaine de l'ingénierie des matériaux, peu de substances peuvent se targuer d'être aussi polyvalentes et fiables que les substances suivantes Acier spécial 60SiCr7 Acier à ressort. Réputé pour sa résistance, sa résilience et sa flexibilité exceptionnelles, cet alliage témoigne de l'ingéniosité de la science métallurgique. Mais qu'est-ce qui distingue exactement cet acier de la myriade d'autres ? Nous allons nous pencher sur sa composition, ses propriétés, ses applications et bien d'autres choses encore pour découvrir les secrets de ses remarquables performances.

la composition et les propriétés

| Modèle | Description |

|---|---|

| 60SiCr7 | Alliage d'acier à ressort comprenant 0,56-0,64% de carbone, 1,50-2,00% de silicium, 0,40-0,70% de manganèse et 0,035% de phosphore. Il est connu pour sa haute limite d'élasticité, son excellente résistance à la fatigue et son impressionnante trempabilité. |

| 60Si2MnA | Semblable au 60SiCr7, mais avec un ajout de manganèse pour améliorer la ténacité et la résistance à l'usure. Largement utilisé dans les systèmes de suspension automobile et les machines industrielles. |

| 60Si2CrVA | Combine le chrome et le vanadium pour une meilleure résistance à la corrosion et une meilleure stabilité thermique. Idéal pour les applications soumises à de fortes contraintes dans l'aérospatiale et les équipements militaires. |

| 55CrMnA | Comprend du chrome et du manganèse pour une meilleure durabilité et une meilleure absorption des chocs. On le trouve couramment dans les ressorts à lames, les ressorts hélicoïdaux et les barres stabilisatrices. |

| 50CrVA | Mélange de chrome, de vanadium et de silicium pour obtenir une résistance à la fatigue et aux chocs supérieure. Un choix populaire pour les ressorts hélicoïdaux à usage intensif et les machines agricoles. |

| 65Mn | Contient 0,62-0,70% de carbone et 0,90-1,20% de manganèse. Il offre une bonne élasticité et une bonne usinabilité, et convient à la production de ressorts plats et de lames. |

| 60Si2CrVA | Incorpore du silicium, du chrome et du vanadium pour une meilleure résistance à la traction et à la fatigue. Utilisé dans les suspensions de course de haute performance et les instruments de précision. |

| 60Si2CrA | Le silicium et le chrome améliorent la dureté et la résistance à la corrosion. Souvent utilisé dans la fabrication de ressorts de fusils et d'instruments chirurgicaux. |

| 55CrMnA | Alliage durable contenant du chrome et du manganèse pour une résilience et une ductilité accrues. Il est fréquemment utilisé dans les systèmes de suspension automobile et les équipements agricoles. |

| 60Si2CrVA | Alliage d'acier polyvalent contenant du silicium, du chrome et du vanadium pour une résistance exceptionnelle à la fatigue et aux chocs. Il est utilisé dans diverses applications allant de l'automobile à l'aérospatiale. |

Applications de l'acier à ressort 60SiCr7

| Application | Description |

|---|---|

| Ressorts automobiles | L'acier spécial 60SiCr7 est largement utilisé dans la fabrication des ressorts de suspension automobile, garantissant un confort de conduite et une longévité optimaux. |

| Machines industrielles | Sa robustesse et sa flexibilité en font un choix privilégié pour diverses applications industrielles, notamment les composants de machines et l'outillage. |

| Matériel de construction | Des crochets de grue aux lames d'excavateur, cet acier offre la résistance et la durabilité nécessaires aux environnements de construction exigeants. |

| Composants aérospatiaux | L'industrie aérospatiale fait appel à l'acier à ressort 60SiCr7 pour ses composants critiques, grâce à sa grande résistance à la fatigue et à sa fiabilité dans des conditions extrêmes. |

| Articles de sport | Qu'il s'agisse de gâchettes de fusils ou de suspensions de course de haute performance, cet alliage excelle dans les applications sportives qui exigent précision et durabilité. |

Spécifications et normes de l'acier à ressort 60SiCr7

| Spécifications | Tailles | Notes | Normes |

|---|---|---|---|

| ASTM | 0,20 mm - 20,00 mm | Grade A | ASTM A229/A229M |

| DIN | 0.50mm - 25.00mm | Note B | DIN 17221 |

| JIS | 0,30 mm - 15,00 mm | Grade C | JIS G4801 |

| ISO | 0,40 mm - 18,00 mm | Grade D | ISO 683-14 |

| GB | 0,25 mm - 12,00 mm | Grade E | GB/T 1222-2007 |

Fournisseurs et prix de l'acier à ressort 60SiCr7

| fournisseur | Informations sur le contact | Fourchette de prix |

|---|---|---|

| Société A | www.companya.com | $500 – $800 |

| Société B | www.companyb.com | $550 – $850 |

| Compagnie C | www.companyc.com | $480 – $750 |

| Entreprise D | www.companyd.com | $520 – $780 |

| Entreprise E | www.companye.com | $490 – $820 |

Comparer les avantages et les inconvénients

Lorsque l'on compare l'acier spécial 60SiCr7 à ses homologues, certains avantages et certaines limites apparaissent :

| Aspect | ressort en acier 60SiCr7 | Alliages concurrents |

|---|---|---|

| Force | Limite d'élasticité et résistance à la fatigue élevées | Varie en fonction de la composition de l'alliage et du traitement |

| Flexibilité | Excellentes propriétés élastiques, offrant une élasticité optimale | Certains alliages peuvent présenter une meilleure ductilité ou une meilleure dureté |

| Résistance à la corrosion | Résistance modérée à la corrosion, peut nécessiter des revêtements protecteurs | Les alliages avec ajout de chrome ou de nickel offrent une protection supérieure. |

| Coût | Prix modéré par rapport à la performance | Le rapport coût-efficacité varie en fonction de l'application et de la demande |

| Usinabilité | Usinable avec l'outillage et les techniques appropriés | Les alliages plus durs peuvent poser des problèmes lors de l'usinage |

FAQ

Q : Qu'est-ce qui distingue l'acier spécial 60SiCr7 des aciers à ressorts conventionnels ?

R : Contrairement aux aciers à ressorts standard, le 60SiCr7 présente une composition soigneusement équilibrée qui privilégie à la fois la résistance et la flexibilité, ce qui le rend idéal pour les applications exigeantes qui requièrent résilience et durabilité.

Q : L'acier spécial 60SiCr7 peut-il résister à des températures élevées ?

R : Bien qu'il présente une bonne résistance à la chaleur, une exposition prolongée à des températures extrêmes peut affecter ses propriétés mécaniques. Pour les applications impliquant des températures élevées, consulter un ingénieur en matériaux afin de déterminer si le produit est adapté.

Q : L'acier spécial 60SiCr7 est-il adapté aux environnements marins ?

R : Bien qu'il offre une résistance modérée à la corrosion, une exposition prolongée à l'eau salée peut nécessiter des mesures de protection supplémentaires telles que des revêtements ou des modifications de l'alliage pour prévenir la corrosion.

Q : Comment le prix de l'acier spécial 60SiCr7 se compare-t-il à celui d'autres alliages d'acier à ressort ?

R : Le coût de l'acier à ressort 60SiCr7 se situe dans une fourchette modérée, offrant un équilibre favorable entre les performances et le prix par rapport aux alliages concurrents.

Q : L'acier spécial 60SiCr7 peut-il être personnalisé pour des applications spécifiques ?

R : Oui, les fabricants peuvent adapter la composition et le traitement thermique du 60SiCr7 pour répondre aux exigences d'applications spécifiques, garantissant ainsi des performances et une longévité optimales.